4

EATON Char-Lynn

Delta Motors Parts and Repair Manual C-MOLO-TS003-E September 2007

Disassembly

Step 1

Cleanliness is extremely

important when repairing

hydraulic motors. Work in a

clean area. Before disconnecting

the hydraulic motor, thoroughly

clean the exterior. Remove

motor from application and

drain the oil from the motor

before disassembly.

Important Note:

All seals

should be replaced when the

motor is disassembled. Front

shell bearing should be replaced

only when shaft is to be

removed.

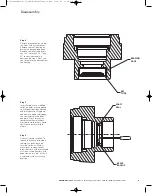

Step 2

Remove the seven bolts and

disassemble the motor in a

vertical position as shown. As

the dowel pins are glued in dur-

ing assembly, they may or may

not come loose.

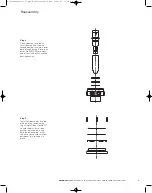

Step 3

Examine condition of bearing

in the valve plate. Replace the

bearing only if signs of wear

and/or contamination are visible.

If necessary remove the bearing

from valve plate by tapping it

with a hammer and a screwdriver.

DeltaPartManual_v7.qxd:HydraulicsTech.qxd 9/19/07 11:40 AM Page 4