5

EATON Char-Lynn

Delta Motors Parts and Repair Manual C-MOLO-TS003-E September 2007

Disassembly

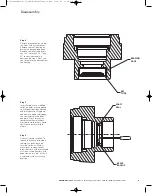

Step 4

Remove grease seal by wedg-

ing it out with a screwdriver.

Remove the shell bearing by

prying the bearing cage open.

Remove the rollers and insert

key (.25” key stock, 2.2” long,

45° recess) horizontally in

between the races. Press the

key to remove the bearing from

the housing.

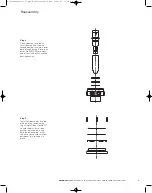

Step 5

Insert flat point of a modified

cotter pin puller (with tip ground

to a flat point) between housing

and brass backup. Wiggle up

and down to begin to dislodge

the seal and work the point

deeper in. Work all the way

round the seal. Some locations

work better than others, some

seals come out easier than

others.

Step 6

Check all mating surfaces. To

reduce the chance of leakage,

replace any parts that have

scratches or burrs. Wash all

metal parts in clean solvent.

Blow them dry with pressurized

air. Do not wipe parts dry with

paper towels or cloth, as lint in

a hydraulic system will cause

damage.

BEARING

RACE

KEY

TOOL

BRASS

BACKUP

SHAFT

SEAL

DeltaPartManual_v7.qxd:HydraulicsTech.qxd 9/19/07 11:40 AM Page 5