WCB11070 (PDF FORMAT)

21

©

Copyright Eaton Corp. 2007, All Rights reserved.

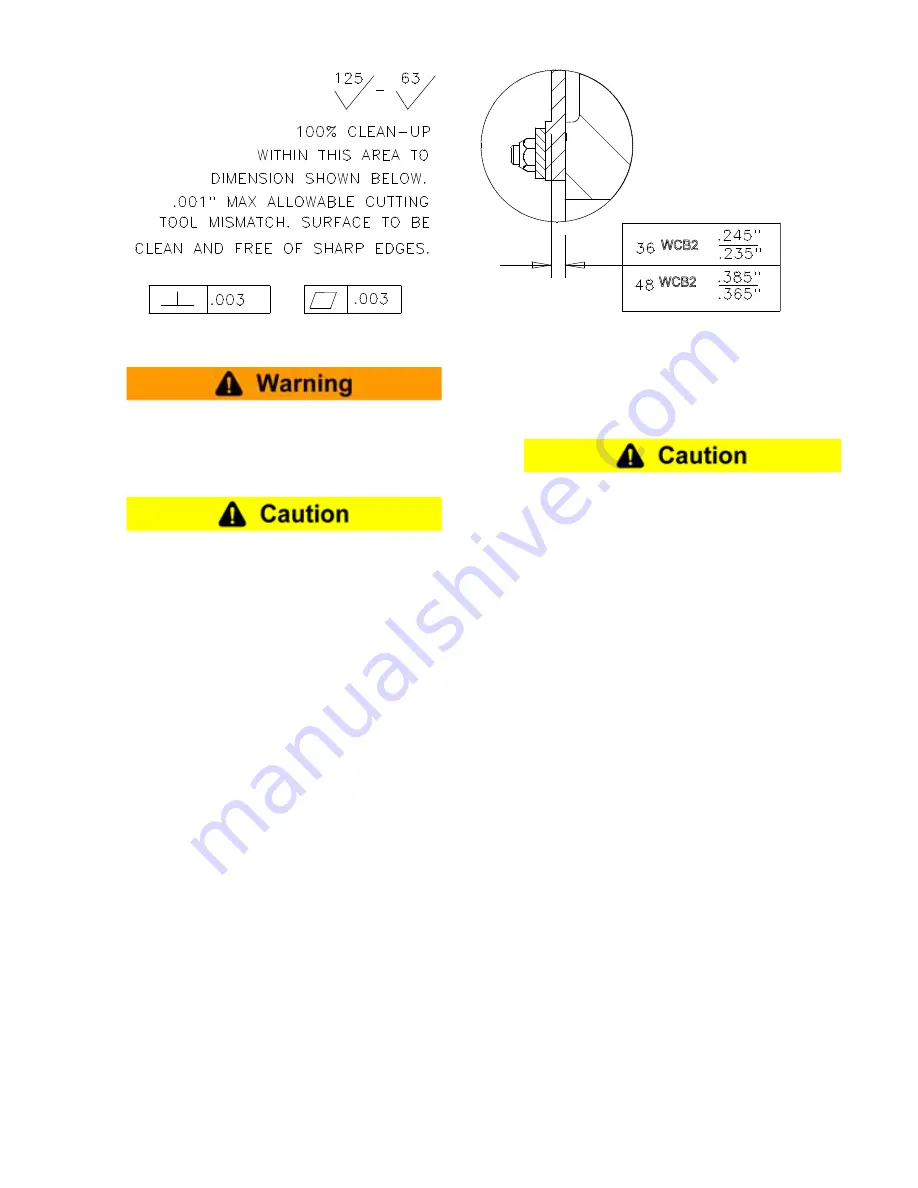

Figure 18

Failure to machine wear plates flat could

result in poor contact between the friction

couple and subsequent reduction or erratic

torque of the tensioner.

After replacement or machining of wear

plates, a minimum wear-in period of four

hours at 50% of the rated horsepower is rec-

ommended for the friction couple to achieve

rated torque.

4.7

Cylinder Seal Replacement

Note :

Note: Item numbers (#) are shown on

Figures

1 and 2

.

4.7.1

Disconnect the air connections.

4.7.2

While supporting the cylinder, loosen the locknuts (18)

ONE TURN AT TIME and in an alternating (crosswise)

pattern until the spring force is completely relieved.

Remove the locknuts and washers (17). Deep well

sockets are required for removal of the locknuts.

4.7.3

Using lifting equipment, carefully remove the cylinder

(19) and piston (33) as an assembly. Set aside in a

clean area.

4.7.4

Place the cylinder and piston assembly with the piston

facing down on blocks approximately 6" (150 mm)

high. The blocks must only contact the cylinder (19) so

that the piston (33) will be free to move out of the cyl-

inder bore.

4.7.5

If a regulated air line is available, the piston can be

partially ejected from the cylinder by applying no more

than 15 PSIG (1.0 bar) to the cylinder.

Application of a higher pressure may cause

damage to the components.

4.7.6

To complete the removal of the piston from the cylin-

der, open all air inlets. Alternately insert a 0.50" (12

mm) diameter by 6" (150 mm) long wood dowel into

each air inlet and gently tap the piston with a mallet so

that it moves evenly out of the cylinder. Be careful not

to damage the sealing surfaces of the piston or cylin-

der by cocking the piston in the cylinder.

4.7.7

Remove the old seals and discard.

4.7.8

Inspect the cylinder sealing surface condition for nicks

or scratches or any other defect which may prevent

the seals from being effective. See Table 13 for wear

limits of the sealing surface. Replace the cylinder, if

necessary.

4.7.9

Thoroughly clean the seal grooves in the piston (#)

and apply a thin, even coat of Dow Corning

®

55 O-

ring lubricant to the piston seal grooves and chamfer

on the piston, the sealing surfaces in the cylinder (19),

and the seals (21)(23).

4.7.10 Install the new seals in the grooves in the piston,

noting the orientation of the seal lips. See

Figure 19

.

Note :

Some assemblies might have used a one piece

bi-directional lip seal. That type of seal has been

superseded by the use of TWO seals that fit

back-to-back as shown in

Figure 19

.

4.7.11 Position the cylinder on a flat, level surface so that the

pressure cavity faces upward.