9

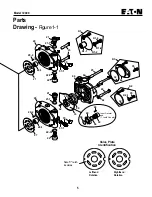

Model 72400

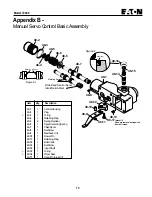

centering the servo piston assembly is required. Measure in

from the left side and set servo piston 12,7 mm [.5 in.] from

surface of housing servo bore as shown in figure 1-5.

Note: Re-adjustment may be required for neutral at unit start-up.

;

12,7 mm

[.5 in.]

Adjust to center piston

Install servo piston

in this direction.

Figure 1-5

5

Install new seal washer, washer, and jam nut to servo

piston bolt. Holding servo piston bolt with hex key wrench

Torque jam nut 17 to 18 N•m [ 150 to 160 lbf•in]. Check the

centering of servo piston assembly. Install new cover plate

gasket and cover plate to left side of servo piston and retain with

four each washers and #10-24 cap screws. Torque cap screws

4,5 to 5,4 N•m [40 to 48 lbf•in.].

6

To assemble cradle sub-assembly, install bushing onto

cradle retaining with button head cap screws. Torque button

head cap screw 1,6 to 1,8 N•m [14 to 16 lbf•in.]

7

Place cradle sub-assembly into housing making sure cradle

is completely seated into housing. Retain cradle sub-assembly

with two cap screws. Torque cap screws 27 to 33 N•m [20 to 24

lbf•ft].

8

To install shaft, place exterior retaining ring, thrust race,

thrust bearing, second thrust race, and second retaining ring

onto shaft. Position washer and shaft seal or spacer onto shaft.

9

Install shaft assembly into front of housing for units with

spacer, retain with interior retaining ring and go on to step 10.

For units with shaft seal, seat seal into position with seal driver

and retain with interior retaining ring.

10 Install servo piston follower onto swashplate dowel pin.

Install swashplate carefully onto bushing (coat bushing surface

with hydraulic oil), aligning servo piston follower with slot in

servo piston assembly.

Disassembly and Reassembly

Housing Inspection:

• Check the bearing (press fit) in housing. If needles

remain in cage, move freely, and setting at the dimension

shown in figure 1-4, removal not required.

1,78 mm

[.07 in.]

Numbered End

Flange End of Housing

Figure 1-4

16 To remove cradle sub-assembly, remove the two cap

screws retaining cradle inside housing. Removing cradle sub-

assembly from housing.

17 Remove button head cap screws (qty. 2) to remove

bushing from cradle.

Bushing Inspection:

• Inspect bushing for contamination embedment within

coating of bushing surface coming in contact with swashplate.

18 Remove all plugs from housing.

19 Discard the shaft seal, gaskets, and o-rings from all

assemblies. Replace with new seals upon reassembly.

Reassembly -

Servo Controlled Piston Pump

1

All parts should be cleaned and critical moving parts

lubricated before reassembly.

2

If necessary, press new bearing in housing to dimension

shown in figure 1-4 with the numbered end of bearing outward.

3

Install the two new seal sub-assemblies into the servo

piston cavity of housing.

4

Screw the cover plate onto the servo piston assembly.

Install new cover plate gasket in place on housing. Install servo

piston assembly and cover plate into servo piston bore in right

side of housing (as shown in figure 1-1 and figure 1-5). Retain

cover plate with four each washers and cap screws. Torque cap

screws 4.5 to 5.4 N•m [40 to 48 lbf•in.]. To obtain neutral,

Front Flange - Drive Shaft End of Pump

Right Side

Left Side