8

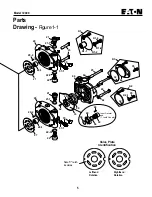

Model 72400

Disassembly

8

Remove housing gasket from housing or endcover.

9

With pump still in vise, remove the six cap screws retaining

the manual servo control assembly. Remove the control

assembly and control housing gasket from the housing.

Remove orifice plates, noting location for reassembly. Remove

nut and lock washer from control arm, remove arm. Note

position of control arm for reassembly.

Refer to Appendix B for disassembly and Inspection of control

assembly.

10 To remove rotating kit assembly from housing, first

remove pump from vise holding the rotating kit assembly in

position. Lower pump so that the shaft end (flange end) is up.

Set the rear of housing onto table with housing flat and rotating

kit assembly at rest on table. (Hole in table, for protruding

shaft, is required.) Lift and remove the housing and shaft from

rotating kit assembly, and swashplate.

11 Remove swashplate from rotating kit assembly and servo

piston follower from swashplate.

Refer to Appendix C for disassembly and Inspection of rotating

kit.

Swashplate Inspection:

• The finish on the piston shoe surfaces of the swashplate

should show no signs of scoring.

• Inspect swashplate bushing surface for wear and surface

for coating transfer from bushing.

12 To remove servo piston assembly from housing, start with

the four each cap screws and washers retaining each cover

plate.

13 In removing the cover plate from the servo piston bolt,

remove jam nut, washer, and seal washer. Hold the servo

piston bolt with hex key and unscrew cover plate off of bolt.

14 Remove servo piston assembly and seal sub-assemblies

(two sets) from housing. Note: Disassembly of servo piston

assembly is not required.

15 Remove retaining ring from the front of housing. Press the

shaft, shaft seal or spacer, and washer from housing. Remove

retaining ring, thrust washer, thrust bearing, second thrust

washer, and second retaining ring from shaft.

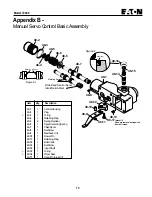

Disassembly -

Servo Controlled Piston Pump

The following instructions apply to a single servo controlled

piston pump with or without a gerotor charge pump. A tandem

pump assembly should be separated into individual pumps

before disassembly.

1

Position the pump into a protected jaw vise, clamping onto

the outer portion of the flange, with the cap screws up. Mark the

relationship of the working ports (for reassembly identification)

to the servo control assembly with a scribe. Remove the four

cap screws retaining endcover.

No gerotor charge pump skip to step 6.

2

Lift the charge pump adapter assembly straight up off

endcover, shaft, and gerotor. Gerotor may stay in adapter or on

endcover.

3

Remove o-ring from charge pump adapter.

4

Remove outer gerotor ring from either the charge pump

adapter or the inner gerotor ring.

Refer to Appendix A for disassembly and inspection of charge

pump adapter assembly.

5

Remove the inner gerotor ring and key from drive shaft or

inner gerotor ring and coupler assembly from shaft.

6

Lift endcover straight up off shaft and housing. Remove

valve plate from endcover or from rotating kit assembly, still in

housing.

7

From endcover, remove bypass valve or plug, and relief

valve assemblies. Note: Mark the relief valve in relationship to

the cavity it was removed, for reassembly purposes.

Endcover Inspection:

• Check the bearing (press fit) in endcover. If needles

remain in cage, move freely, and setting is at the dimension

shown in figure 1-3, removal not required.

• Check roll pin in endcover. If tight and set to the

dimension shown in figure 1-3, removal not required.

4,39 mm

[.173 in.]

2,29 mm

[.09 in.]

Numbered End

Figure 1-3