16

Model 72400

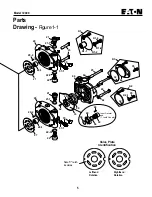

Appendix C -

Rotating Kit Assembly

Disassembly -

Rotating Kit Assembly

Disassembly of rotating assembly is required for inspection

only.

1

Remove the nine piston assemblies, shoe retainer, and

shoe retainer pivot from cylinder barrel.

Inspection:

• Examine the O.D. of the pistons for finish condition.

They should not show wear or deep scratches. Inspect the

shoes for a snug fit on the ball end of the pistons and a flat

smooth surface that comes in contact with the swashplate. Do

not lap piston shoes.

• Examine the shoe retainer for wear in the pivot area.

• Examine the pivot to insure smoothness and no signs

of wear.

• Inspect the cylinder barrel surface that makes contact

with valve plate. This surface should be smooth and free of

deep scratches. Do not lap piston block.

• The pistons should move freely in the cylinder barrel

bore. If they are sticky in the bore, examine the bore for scoring

or contamination.

2

To inspect pins and spring caution should be taken in

removing spring. The spring is highly compressed and the

retaining ring should not be removed without compressing the

spring safely.

The following parts are required to disassemble the cylinder

barrel:

2 ea.

3/8 in. I.D. x 1-1/8 in. O.D. flat washers

1 ea.

3/8 in. x 3-1/4 in. N.C. cap screw, and

1 ea.

3/8 in. N.C. nut

To remove spring, place one of the flat washers over the 3/8 in.

x 3-1/4 in. cap screw. Put cap screw through the center of the

cylinder barrel and apply the second washer. Let washer rest on

the three pins and retain with nut. Turning nut and compressing

spring inside the barrel. Use a pair of retaining ring pliers and

remove the internal retaining ring. Remove nut, bolt, and the

two washers from barrel. Remove the washer, spring, second

washer, three pins, and pin keeper at the same time.

Reassembly -

Rotating Kit Assembly

1

To reassemble the rotating kit assembly complete the

following: Compress the pin keeper and install in the spline of

the cylinder barrel. Install the three pins with head end to the

inside of the barrel and position in the special grooves of the

cylinder barrel spline.

2

Install the washer, spring, and second washer into the

cylinder barrel. Use the two 3/8 in. I.D. washers, nut, and 3/8 in.

x 3-1/4 in. cap screw to compress the spring and retain with

retaining ring. Remove the nut, cap screw, and the two

washers.

3

Install the pivot onto the three pins, shoe retainer on the

pivot, and piston assemblies thru the shoe retainer and into

cylinder barrel, resting on shoe retainer.

Item

Qty.

Description

8-1

9

Piston assemblies

8-2

1

Shoe Retainer

8-3

1

Shoe Retainer Pivot

8-4

1

Retainer

8-5

1

Cylinder Barrel

8-6

3

Pins

8-7

2

Washer

8-8

1

Spring

8-9

1

Retaining Ring

8-1

8-2

8-3

8-5

8-4

8-6

8-7

8-8

8-9

8-7