21

EATON

Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004

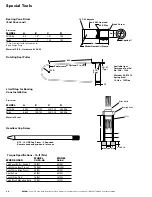

Swashplate

Thrust Plate

Piston Shoe

Spacer

Retaining

Strap

Cap Screw

Piston

Shoe Retainer

Plate

A

B

C .008 in. Max

A

(Spacer Height)

– B

(Shoe Retainer Plate)

= C

(Fixed Clearance .008 Max)

2. Before assembling motor any

further, you must check the

fixed clearance of motor.

Measure the height of

retaining strap spacer with a

micrometer or vernier calipers.

There are two fixed spacer

heights – one for the 33, 39,

46 units and one for the 54, 64

units. Spacers are critical to

the unit design and may not

be interchanged.

3.

Measure combined thickness

of both piston shoe flange and

shoe retainer plate.

Subtracting this measurement

from spacer height gives fixed

clearance of unit.

4.

Fixed clearance must not

exceed .008 inches [,20 mm].

If fixed clearance exceeds .009

inches [,02 mm], replace worn

parts, (i.e., piston shoe sub-

assemblies, thrust plate,

retaining strap and/or shoe

retainer plate).

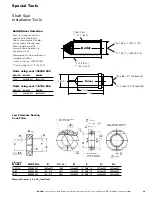

1. Lubricate and install shoe

retainer plate and piston

shoes in cylinder barrel

subassembly. After installa-

tion, freely lubricate brass

shoe faces with clean

hydraulic fluid.

Rotating Group

Before reassembly, clean

all parts and assemblies

in clean solvent and

blow them dry with

compressed air. Inspect

and replace all scratched

or damaged parts. When

reworking parts. Do not

use coarse grit paper,

files or grinders on any

finished surfaces.

Replace all gaskets and

O-rings.

Lubricate O-rings with

petroleum jelly for

retention during

reassembly. Freely

lubricate all bearings and

finished part surfaces

with clean hydraulic

fluid. This will provide

required start-up

lubrication for moving

parts.

Note:

An alternate method of

checking fixed clearance is

with the use of a feeler

gauge. If using this method,

make sure gauge is inserted

between retaining strap and

shoe retainer plate only.

Piston shoe faces could be

damaged if gauge is inserted

between piston shoe and

thrust plate.

Check Fixed Clearance

Assembly