20

EATON

Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004

Critical

Sealing

Area

Critical

Sealing

Area

Drift

Punch

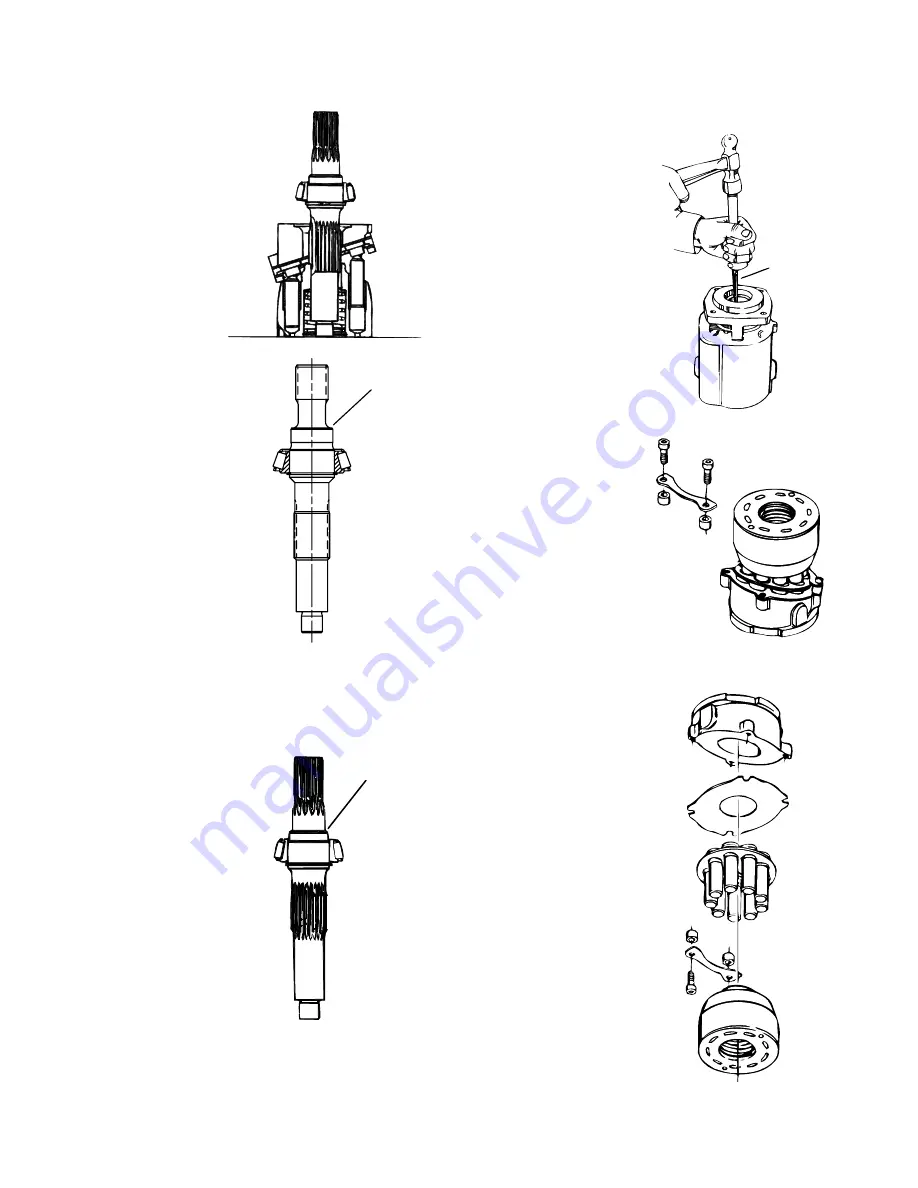

30. Position the shaft/cylinder

barrel subassembly with the

shaft facing up. Carefully lift

out the output drive shaft

subassembly.

31. When bearing cone must be

replaced, use a press to

remove cone from

shaft subassembly.

Important:

When

removing or installing bearing

cone, do not damage shaft

sealing area (stepped area

between bearing journal and

output drive shaft splines).

This area is critical for sealing

the shaft seal.

31.a. You must use special stop

limit tool (refer to Special

Tools) when installing new

cone.

32. If bearing cup needs replacing,

carefully remove the cup using

a hammer and drift punch.

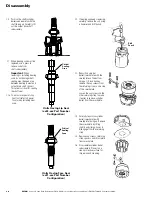

Units Having Face Seal

(xx31-xxx Part Number

Configuration)

Units Having Lip Seal

(xx33-xxx Part Number

Configuration)

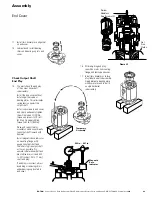

Disassembly

33. Reposition cylinder

barrel/swashplate with the

swashplate on the bottom.

Using a 1/4-inch hex key,

remove the cap screws from

the retaining strap on one side

of the swashplate.

Loosen the cap screws on the

other retaining strap to make

it easier to remove cylinder

barrel from the swashplate.

34. Carefully reposition cylinder

barrel/swashplate with

swashplate facing up. Remove

the swashplate by lifting

slightly and sliding it over to

disengage from the retaining

strap.

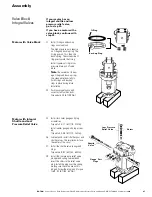

35. Remove cap screws, retaining

strap, spacers and thrust plate

from swashplate.

36. Disassemble cylinder barrel

subassembly. Place it on a

clean protective surface for

inspection and cleaning.