19

EATON

Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004

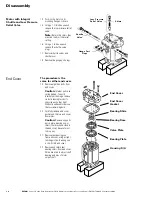

23. Remove end cover gasket and

dowel pins from motor

housing. Gasket may have

remained on end cover during

removal.

24. Remove bearing plate and pins

from cylinder barrel. If using a

small screwdriver to pry bear-

ing plate from cylinder barrel,

make sure bearing plate and

barrel surfaces are not

scratched or damaged.

Important:

Handle the

bearing plate and valve plates

with extreme care. They are

lapped to extremely close

tolerances for flatness.

25. Install bearing puller and

remove bearing from output

shaft (refer to Special Tools).

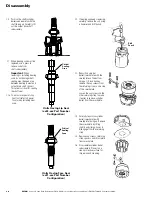

Rotating Group

Hub Puller and

Low Clearance

Bearing Puller

(refer to

Special Tools)

Use extreme care when handling all

close tolerance internal parts of motor.

Keep parts clean.

Low clearance bearing puller is recommended for

removal of end cover bearing cone. The bearing puller

pulls against bearing rollers, not against inner cup. It

is designed to prevent bearing cone and cylinder

barrel face from being damaged when bearing is

removed. Low clearance between end cover bearing

and cylinder barrel makes it difficult to use any other

type of bearing puller.

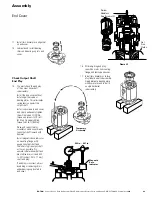

26. Carefully reposition motor on

its side. Using 1/4 in hex bit

socket, remove the two cap

screws that hold swashplate

in the housing.

27. Remove and discard sealing

washers from cap screws.

Replace with new sealing

washers.

28. Push inward on shaft

assembly to dislodge the

swashplate from its pocket in

housing.

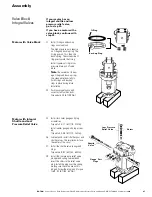

29. Carefully remove output

shaft/cylinder barrel assembly

from housing.

Disassembly