26

EATON

Series 1 Heavy Duty Hydrostatic Fixed Displacement Motors Parts and Repair E-MOPI-TS002-E September 2004

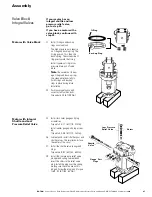

Note:

Lip seal kits come with a

shaft seal, retaining ring, and

spacer. The spacer is only

required for units that have

extensive use in the field. The

spacer puts the seal in a new

location on the shaft sealing

area. If using the spacer, install

the spacer between the shaft

seal and the retaining ring in

step f.

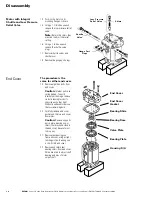

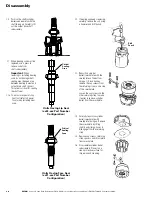

Units Having Lip Seal

(xx33-xxx Part Number

Configuration)

Ensure the shaft sealing surface and housing seal bore

are clean and free of all dirt and debris to avoid

introducing any contaminants into unit.

1. Grease the inside surface of seal that contacts shaft.

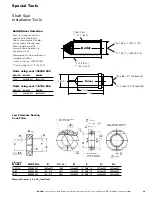

2. Select correct bullet and driver. Bullet and drive

shaft chamfer must align with each other leaving

no gap between the bullet and shaft. Bullet should

pilot on shaft diameter so bullet cannot shift side to

side, allowing step between bullet and shaft seal

diameter.

3. Press the new, greased shaft seal over a shaft bullet.

Closed face of the shaft seal faces the closed end of

the bullet.

4. With the shaft seal on the bullet, insert bullet over drive

shaft and into the seal pocket. Take care to ensure seal is

properly aligned with housing bore as seal is pressed in to

minimize chance of damaging seal.

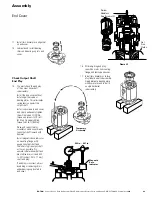

5. Using the driver and a mallet, push the seal until the tool

bottoms on the pilot of flange.

6. Remove the tool and insert the retaining ring into the seal

pocket. A spacer is required, whenever there is a

significant groove in the shaft from the seal. (A maximum

of two spacers may be used before the shaft must be

replaced), place it between the shaft seal and the

retaining ring.

7. Using the tool and mallet, drive the seal, spacer(as

required if using, and retaining ring in until the retaining

ring snaps into place in the groove.

Driver

Bullet

Motor Housing

Shaft

Assembly