19

Installation and Operation of Flexible Batch Broiler – Electric

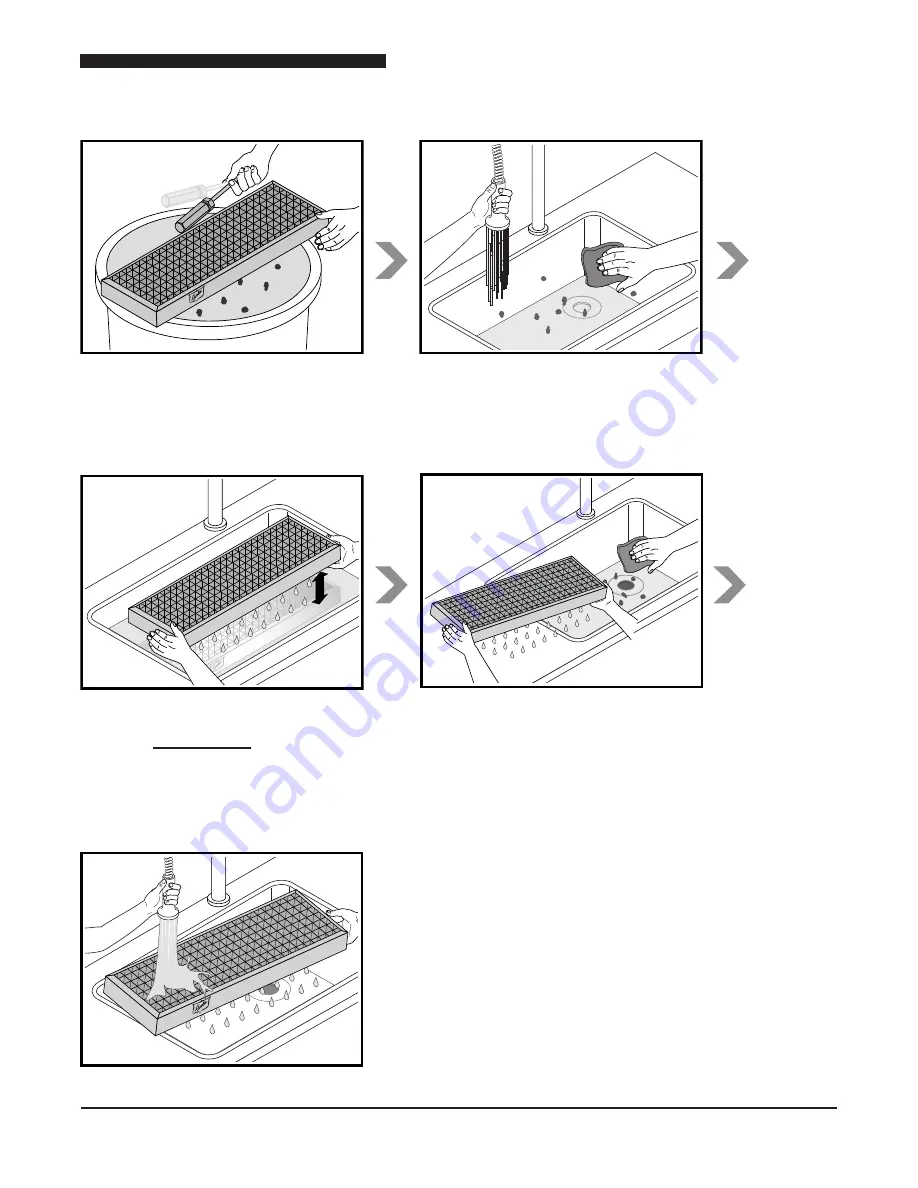

C-3. Weekly Cleaning (cont’d)

Gently tap frame of the catalyst while

holding over a waste bin to dislodge any

loose ash/carbon particles.

Begin with a clean sink and remove

all foreign matter from any wash

basin used, before starting the

catalyst washing process.

Partially fill wash basin, that is large

enough to accommodate the catalyst, with

enough clean hot water (100-130ºF) to

completely cover the catalyst when placed

into the basin. Agitate the catalyst up and

down in the water a few times and then let it

soak for 20 minutes.

Remove the catalyst and shake out the

excess water. Drain and clean the basin

thoroughly and then repeat step 3.

Remove the catalyst and rinse thoroughly with a large

volume of hot water. The typical restaurant dishwashing

spray nozzle (low pressure, high volume) is perfect for

this operation. Work the spray slowly over the entire

surface both front and back to assure the removal of any

particles caught in the catalyst face or behind the frame.

Shake the remaining water from the catalyst and then let

it air dry overnight. The catalyst can then be reinstalled

in the broiler. Ensure that the catalyst guard is re-

installed over the catalyst prior to turning on the broiler.

Содержание FBB-EC-208

Страница 2: ...Installation and Operation of Flexible Batch Broiler Electric 2...

Страница 24: ...Installation and Operation of Flexible Batch Broiler Electric 24 B USER REPLACEABLE HEATING ELEMENTS...

Страница 25: ...25 Installation and Operation of Flexible Batch Broiler Electric B USER REPLACEABLE HEATING ELEMENTS CONT D...

Страница 26: ...Installation and Operation of Flexible Batch Broiler Electric 26 B USER REPLACEABLE HEATING ELEMENTS CONT D...

Страница 27: ...27 Installation and Operation of Flexible Batch Broiler Electric B USER REPLACEABLE HEATING ELEMENTS CONT D...

Страница 30: ...Installation and Operation of Flexible Batch Broiler Electric 30 VI WIRING SCHEMATICS...

Страница 31: ...31 Installation and Operation of Flexible Batch Broiler Electric...