11

Donaldson Company, Inc.

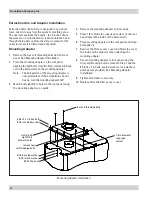

Downtime Cleaning

With Motor Starter

The downtime cleaning control panel with motor starter

requires three-phase power with the requirements as

listed on the motor’s nameplate and is wired directly to

the terminals on the motor disconnect switch located

inside the control panel. See wiring diagram inside

control panel.

Delta P Cleaning

With Motor Starter

The Delta P control panel with motor starter requires

three-phase power with the requirements as listed on the

motor’s nameplate and is wired directly to the terminals

on the motor disconnect switch located inside the

control panel. See wiring diagram inside control panel.

Downtime Cleaning with Motor Starter

L3

L2

L1

1L3

1L2

1L1

ground lug

PE PE

1L1

1L2

3-Phase

OL

M1

fused

disconnect

30A

M1

blower

motor

3-ft blower

motor cable

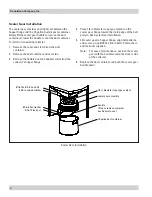

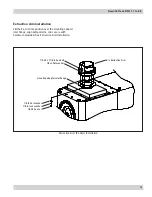

Downtime Cleaning without Motor Starter

G ground lug

TR1

L

N

N

N

FU1

PS1

N

L

G

120-Volt AC

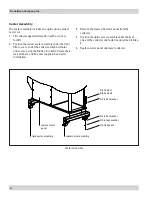

Delta P Cleaning with Motor Starter

L3

L2

L1

1L3

1L2

1L1

ground lug

PE PE

1L1

1L2

3-Phase

OL

M1

fused

disconnect

30A

M1

blower

motor

3-ft blower

motor cable

Delta P Cleaning without Motor Starter

SEQ1

SV2

SV1

SV3

120-Volt

ground

lug

FU1

Without Motor Starter

The downtime cleaning panel without motor starter

requires 120-Volt AC, single-phase power to be wired

directly to the control panel terminal block at Terminals

L, N, and G. Separate power must be supplied directly

to the motor. See the wiring diagram on the motor's

nameplate and Motor Wiring Instructions.

Without Motor Starter

The Delta P control panel without motor starter requires

120-Volt AC, single-phase power to be wired directly to

the control panel two-point terminal block located on the

3-pin timer subpanel. Separate power must be supplied

directly to the motor. See the wiring diagram on the

motor's nameplate and Motor Wiring Instructions.