User manual in Original

Doc. ref: 500A_MB_am_en_210602

DISPERATOR AB

Tel: 08-724 0160

E-mail: [email protected]

Mälarvägen 9, 141 71 Segeltorp

Web page: www.disperator.se

37 / 41

36 / 41

9.5. Assembly of Disposer

1. Clean all components carefully. Wipe the surface of the motor (P1) upper flange and its shaft.

Make sure that there is no dust or grease residue.

2. Make sure that the motor shaft key (P30) is in the correct position. Apply a thin layer of

Disperator special grease (P26) on the motor shaft.

3. Wipe the carrier (P2) clean on the inside and outside.

4. Mark onto the motor shaft the depth of the hole in the carrier (P2). From the top of the motor

shaft, this measure is 38 mm for models 510, 515, and 48 mm for model 520, and 58 mm for

models 530, 550 and 575. Carefully press the carrier (P2) onto the motor shaft all the way down

to the mark. If hand power is not enough, use the axle screw (P12) as a mounting tool. If needed,

use the rotary shredder (P10) as a handle to prevent the carrier from rotating.

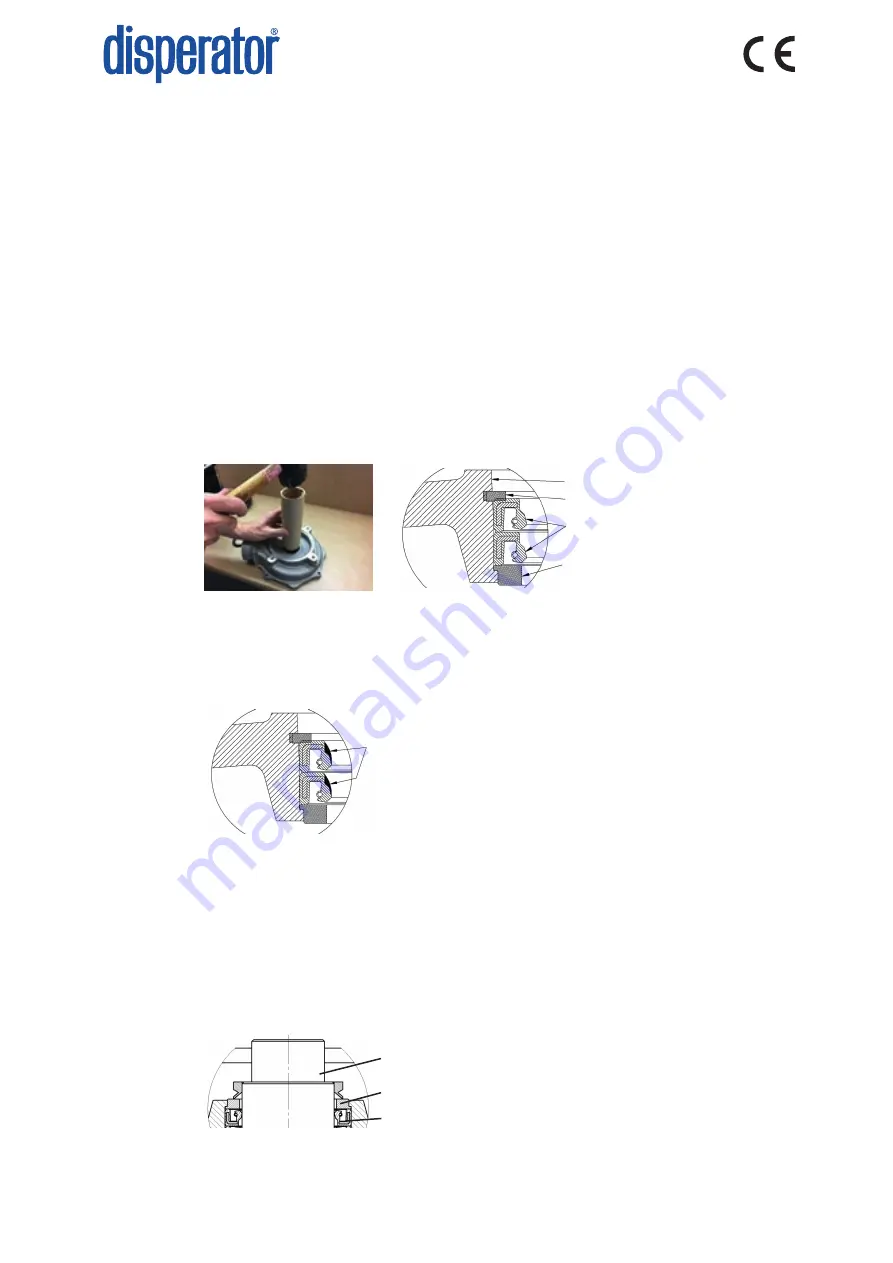

5. On the end shield (P3), clean the center hole for the axle seals (P5).

6. Place the washer (P4) in the end shield with the flange facing towards the motor (see the sketch

below under item 8, where the parts are seen with the end shield placed upside down as on the

photo to the left).

7. Grease the sealing face of this center hole in the end-shield (P3) with special grease (P26).

8. To avoid damaging the seals (P5, 2pcs), press each seal one at the time into position in the end

shield using a tool (for example a shaft end or other round bar, see below photo) that has the

same outer diameter as these seals. The seals shall be placed with the opening and stainless

spring upwards towards the washer (P4) according to the below sketch.

9. The seals are fixated by fitting the locking ring (P6) into the groove in the end shield (P3)

according to the above sketch under item 8. Tap on this ring to ensure that it is seated properly

in the groove in the end shield.

10. With a clean and soft putty knife fill the grooves along the sealing lips in the axle seals (P5) with

special grease (P26). Be sure no dirt or particles happen to fall into this greasing.

11. With a clean soft cloth lubricate a thin layer of special grease (P26) on the carrier (P2) sealing

surface for the

axle seals (P5)

.

12. With reference to section 9.4, item 13 above, refit the end shield (P3) so that its outlet ends up

180° offset from the motor (P1) terminal box for cable connection.

Take great care so that the

lips on the axle seals

(P5, 2pcs)

not

are damaged. For disposer models 510, 515 and 520 secure

the end shield with tightening torque 47 Nm on the four screws (P7), and for models 530, 550

and 575 secure the end shield with tightening torque 81 Nm on the four screws (P7).

13. Grease the sealing lip of the V-ring seal (P8) and its seal washer (P4) using special grease (P26).

Fit the V-ring seal over the carrier (P2) with its seal lip against the seal washer (P4).

P3

P6

P5

P4

P26

P2

P8

P4

Содержание EXCELLENT 500A-MB Series

Страница 2: ......