8

TIG welding with “Lift”

In the TIG process welding is achieved by melting the two metal

pieces to be joined, with the possible addition of material from

the outside, using an arc ignited by a tungsten electrode. The

“Lift” type ignition used in

DIX PI 3506.M I / DIX PI 3006.M I

Puls / DIX PI 3506.M I Puls

equipments makes it possible to re-

duce tungsten inclusions on ignition to a minimum. The molten

bath and the electrode are protected by and inert gas (for ex-

ample, Argon). This type of welding is used to weld thin sheet

metal or when elevated quality is required.

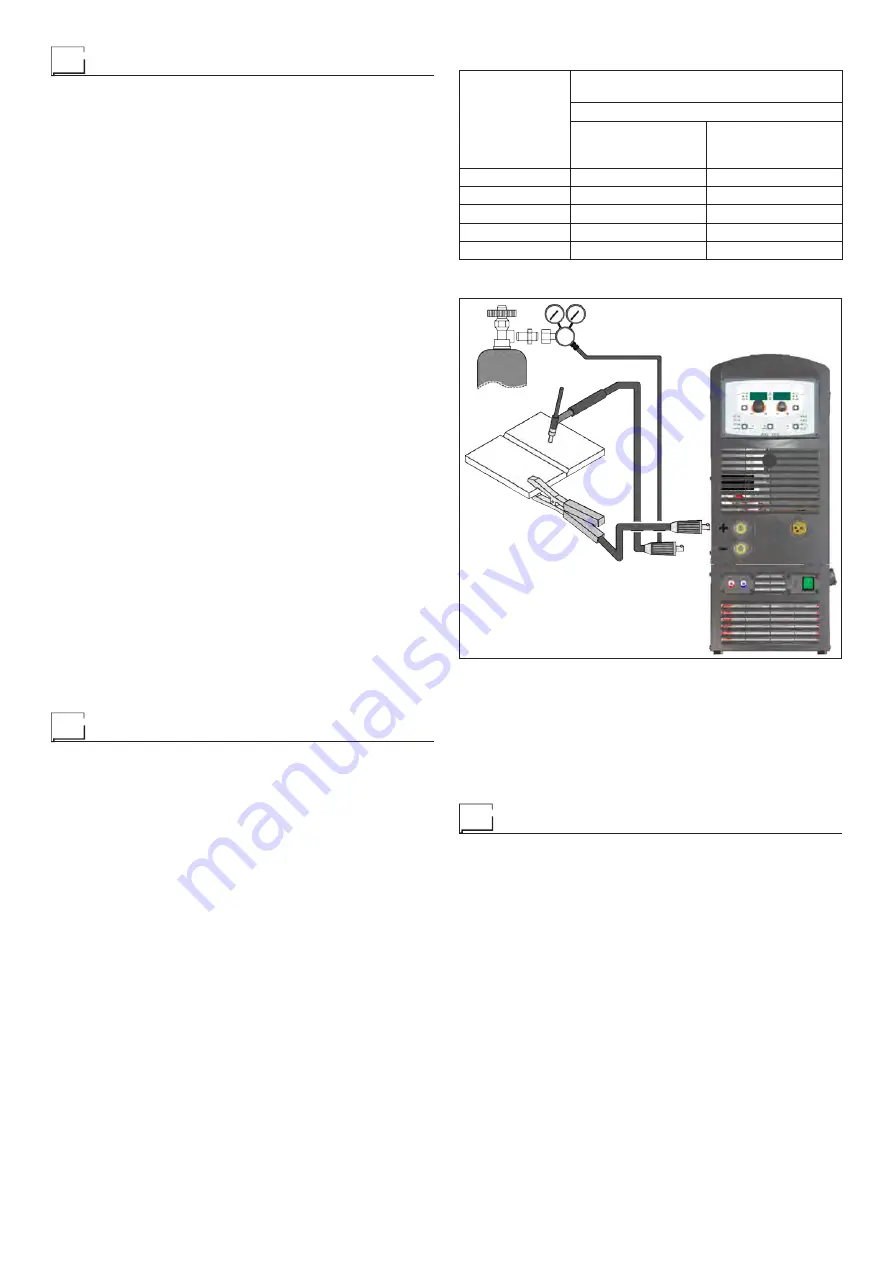

1) Connecting the welding cables (Fig. F):

•

Connect one end of the gas hose to the gas connecter on

the TIG torch and the other end to the pressure reducer

on the inert gas cylinder (Argon or similar).

•

With the welding power source switched off:

- Connect the ground cable to the snap-on connector

(positive).

- Connect the relative ground clamp to the workpiece or

to the workpiece support in an area free of rust, paint,

grease, etc..

- Connect the TIG torch power cable to the snap-on con-

nector marked - (negative).

2) Switch the welding welding power source on by moving the

power supply switch to I (Pos. 7, Fig. B).

3) Make the adjustments and do the parameter settings on

the control panel.

4) Open the gas cylinder and regulate the flow by adjusting

the valve on the TIG torch by hand.

5) Ignite the electric arc by contact, using a decisive, quick

movement without dragging the tungsten electrode on the

piece to be welded (“Lift” type ignition).

6) The welder has a SWS “Smart Welding Stop” system for

the end of TIG welding. Lifting up the torch without switch-

ing off the arc will introduce a slope down and it will switch

off automatically.

7) When you have finished welding remember to shut the

valve on the gas cylinder.

Table 5 shows the currents to use with the respective elec-

trodes for TIG DC welding. This input is not absolute but is for

your guidance only; read the electrode manufacturers’ instruc-

tions for a specific choice. The diameter of the electrode to use

is directly proportional to the current being used for welding.

Maintenance

ATTENTION:

Cut off the power supply to the equipment be

-

fore effecting any internal inspection.

DIX PI 3006.M I / DIX PI 3506.M I / DIX PI 3006.M I Puls /

DIX PI 3506.M I Puls

IMPORTANT:

For fully electronic welding welding power sourc

-

es, removing the dust by sucking it into the welding power

source by the fans, is of utmost importance.

In order to achieve correct functioning of the welding power

source, proceed as described:

•

Periodic removal of accumulations of dirt and dust inside the

equipment using compressed air. Do not point the jet of air

directly at the electrical parts as this could damage them.

•

Periodical inspection for worn cables or loose connections

that could cause overheating.

TORCH

The torch is subjected to high temperatures and is also stressed

by traction and torsion. We recommend not to twist the wire and

not to use the torch to pull the welder. As a result of the above

the torch will require frequent maintenance such as:

•

Cleaning welding splashes from the gas diffuser so that the

gas flows freely.

•

Substitution of the contact point when the hole is deformed.

•

Cleaning of the wire guide liner using trichloroethylene or

specific solvents.

•

Check of the insulation and connections of the power cable;

the connections must be in good electrical and mechanical

condition.

Table 5

Ø ELECTRODE

(mm)

ELECTRODE TYPE

Current adjustment field (A)

TIG DC

Tungsten

Ce 1%

Grey

Tungsten

Rare ground 2%

Turchoise

1

10-50

10-50

1,6

50-80

50-80

2,4

80-150

80-150

3,2

150-250

150-250

4

200-400

200-400

FIG. F

SPARE PARTS

Original spares have been specifically designed for our equip-

ment. The use of spares that are not original may cause vari-

ations in the performance and reduce the safety level of the

equipment. We are not liable for damage due to use of spare

parts that are not original.

Optional

AIR AND/OR WATER COOLED UP/DOWN TORCH

This command and works as an alternative:

•

To the ENCODER - SX knob on the welding welding power

source’s control panel. In “synergic” MIG MAG and “manual”

MIG MAG welding processes, by pressing the two right (+)

and left (-) buttons you can regulate the values for the syn-

ergic welding parameters.

•

To the ENCODER - DX knob on the welding welding pow-

er source’s control panel. In the JOB welding process, by

pressing the two right (+) and left (-) buttons you can scroll

the welding points set previously.

Содержание DIX PI 3006.M I Puls

Страница 12: ...12 2101AC34 DIX PI 3006 M I DIX PI 3506 M I...

Страница 13: ...13 2101AC33 DIX PI 3006 M I Puls DIX PI 3506 M I Puls...