Product Information

Safety technics modular generation in metal housing version 08 dated: 2009-04-10 page 19 from 32

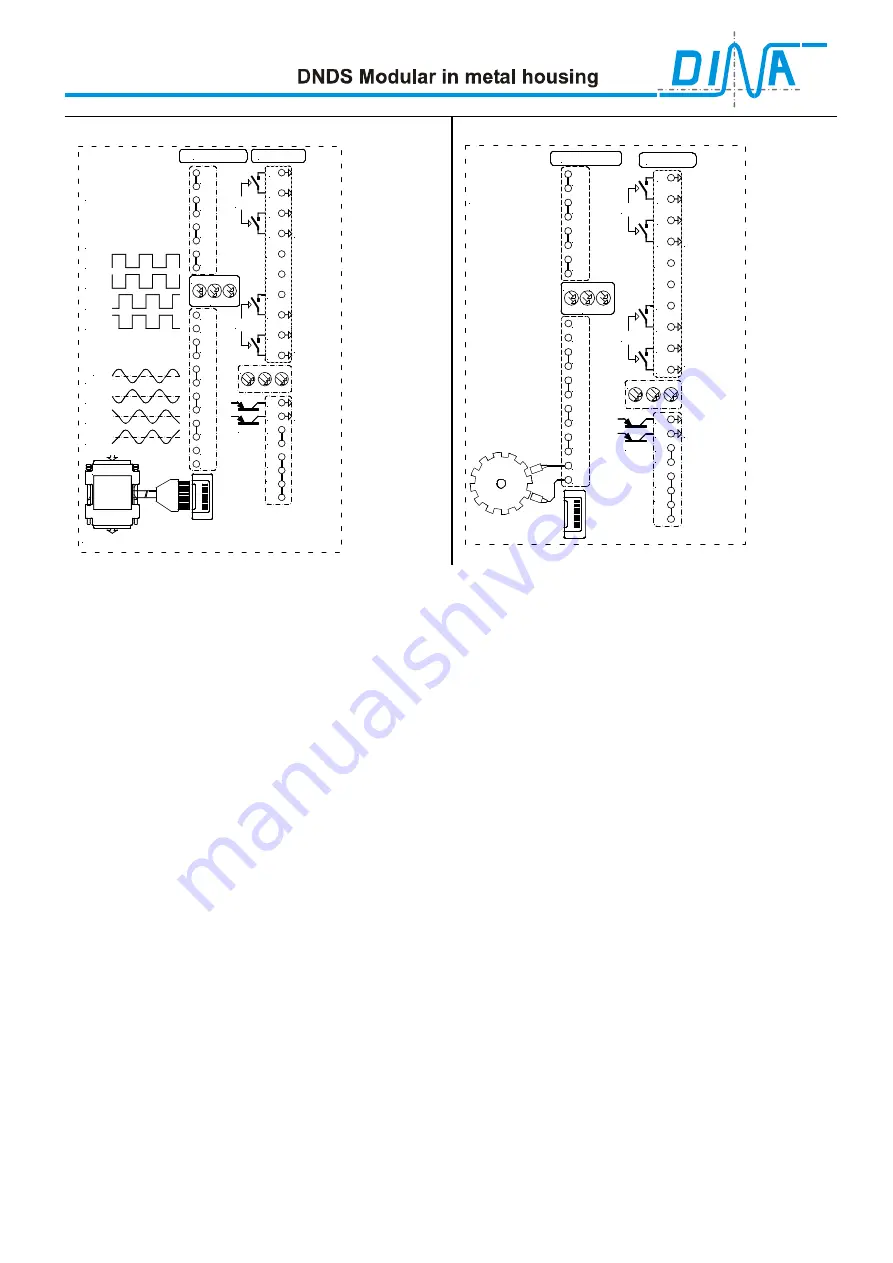

Motion detection via an encoder

Motion detection via 2 PNP proximity sensors

SPEED

UB

STOP

IN2

IN1

D1

D2

D3

D4

SH

R1

D5

D6

M11

M12

ENCODER

Measuring system

DNDS 1PMG

Inputs

outputs

Drives

shutdown,

Emergency

shutdown,

two canal

or series

connection

security

cover

lock

two canal

or series

connection

STOP SPEED

UB

OD

OS

A2

A1

0V

24V

44

43

34

33

24

23

14

13

SPEED

STOP

NC

NC

SPEED

STOP

Information

only

A

A*

B

B*

Sin

Sin*

Cos

or 1Vss

Cos*

1V-5V TTL

Inputs

DNDS 1PMG

SPEED

UB

STOP

IN2

IN1

D1

D2

D3

D4

SH

R1

F1

F2

F3

F4

outputs

Drives

shutdown,

Emergency

shutdown,

two canal

or series

connection

security

cover

lock

two canal

or series

connection

STOP SPEED

UB

OD

OS

A2

A1

0V

24V

44

43

34

33

24

23

14

13

SPEED

STOP

NC

NC

SPEED

STOP

Information

only

Requirements of the encoder

•

Encoder signal: Rectangular with amplitude of 0.5-5 V or sine/cosine signal with 1VSS.

•

Encoder frequency

≤

≤

≤

≤

300KHz

•

Encoder with high resistance outputs during malfunction.

•

2 tracks 90° out of phase, 2 signals per track that are 180° out of phase

•

The signals of encoder are not allowed to be generated synthetically

Fundamental

•

The monitoring of the Standstill on zero is not possible.

•

The monitored standstil frequency is 5Hz after the divisor with Encoder measurement messsystem. With resolver

measurement messsystem the change of the phase is monitored.

•

With Encoder select a large relationship mode2/ Standstill as possible: With axis 10 to 20, with spindles 20 to 50.

•

The divisor with mode 2 is if possible > 10.

•

With (mode 1/ mode 2)>(1250Hz/ mode 2-Freq) requires divisor variable

•

With divisor variable the divisor with mode 2 must be

≤

≤

≤

≤

2(31+1) or

≤

≤

≤

≤

4(31+1).

Monitoring not used

If less than 8 actuations should be monitored the not used monitoring modules must be removed from the unit and

replaced by a bridge circuit connector.

Bridge Circuit connectors

can be ordered from DINA.

Disable monitoring

If one monitoring system should be disabled, this could be done by connecting the input IN2 to 24V.

Faults and Errors

•

LED “SPEED” and “STOP” on the input and output modules do not light:

- The encoder is not connected.

- A proximity sensor failure.

•

LED “SPEED” and “STOP” on the monitoring module flash in 1 Hz intervals:

- Track A or B of encoder is missing.

- Proximity sensor at IN1 or IN2 is defective.

•

LED “SPEED” dos not light

- Registration of last crossing of the adjusted maximum speed.

To clear a fault the supply voltage must be switched off for at least 2s to reset the equipment (disconnect A1).

•

LED “STOP” and LED “SPEED” on the monitoring module flash in 2 Hz intervals:

- DNDS internal error.

- Error by improperly installed external signal lines.

The fault can possibly be eliminated by interruption of A1 for at least 2s.

Содержание DBDS 1VMG

Страница 1: ...DNDS Modular in metal housing Product information Safety for men and machines...

Страница 32: ......