CYCLE RATES

These tools are designed to operate up to the following

cycle rates:

Intermittent Operation

– 16-17 nails per minute

Continuous Operation

– 1000 nails per hour

Exceeding these rates could cause the tool to overheat,

resulting in loss of performance or damage to tool

components. By using the nailer at its recommended cycle

rate, you will be able to drive several thousand nails in a

typical working day.

SAFETY TRIP

These tools are supplied fitted with a sequential safety trip

and are marked with an inverted equilateral triangle (

▼

).

Do not attempt to use a tool marked in this way if the

safety trip is missing or appears damaged.

The sequential trip requires the operator to hold the tool

against the work with the safety trip depressed before

pulling the trigger. In order to drive additional fasteners, the

trigger must be released and the tool lifted away from the

work, before repeating.

This makes accurate fastener placement easier, for

instance on framing, toe nailing and crating applications.

The sequential trip allows exact fastener location without

the possibility of driving a second fastener on recoil. The

sequential trip tool has a positive safety advantage because

it will not accidentally drive a fastener if the tool is contacted

against the work or anything else, while the operator is

holding the trigger.

FASTENER LOCKOUT

These tools

employ a mechanism to prevent dry firing of

the tool.

When the magazine is not loaded with nails or when the

remaining number of nails becomes less than 4/5, the

contact arm cannot operate and the tool will not fire.

TOOL OPERATION CHECK

SEQUENTIAL TRIP OPERATION

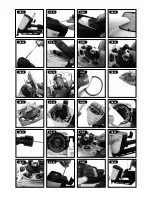

A) Without touching the trigger, press the contact arm

against the work surface.

THE TOOL MUST NOT CYCLE.

B) Hold the tool off the work surface and, avoiding to point

the tool at yourself or others, pull the trigger.

THE TOOL MUST NOT CYCLE.

C) With the tool off the work surface, pull the trigger. Press

the safety trip against the work surface

THE TOOL MUST NOT CYCLE.

D) Without touching the trigger, press the safety trip against

the work surface then pull the trigger.

THE TOOL MUST CYCLE.

TOOL USE

Having checked that the tool is working properly, press the

nose against the work piece and pull the trigger. Check

whether the fastener has been driven as required (Fig. 14).

ADJUSTING THE NAILING DEPTH

To ensure that each nail penetrates to the same depth,

be sure that the tool is always held firmly against the

workpiece.

If nails are driven too deep or shallow into the workpiece,

adjust the nailing in the following order:

1. Remove the fuel cell and the battery from the tool (Fig.

15).

2. If nails are driven too deeply, move the contact arm

forward. If nails are driven too shallow, move the contact

arm backward (Fig. 16).

3. Stop moving the contact arm when a suitable position is

reached for a nailing test.

4. Connect the fuel cell and the battery to the tool.

ALWAYS WEAR EYE PROTECTION.

Perform a nailing test.

5. Remove the fuel cell and the battery from the tool.

6. Make further adjustments until the drive depth is correct,

testing after each adjustment.

7. UTILITY HOOK

These tools have a utility hook installed in the magazine.

Maintenance & troubleshooting

Remove the fuel cell and battery from the tool and completely

empty the magazine before starting maintenance or repairs.

Read and understand the warnings in this manual, in the

Tool Technical Data and on the tool itself and use extra care

when evaluating problem tools.

14

Содержание DGN9033-XJ

Страница 2: ...DGN9033 XJ ...

Страница 4: ...3 ...