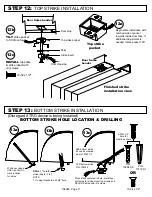

104948 Page 18

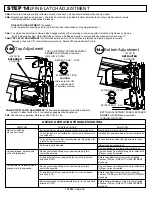

STEP 14:

FINE LATCH ADJUSTMENT

14a.

Ensure that latches are fully retracted. Gently close door. Latches should extend when door is closed.

14b.

Depress pushpad and open door. Top latch should clear top strike & bottom bolt should not drag. Latches should remain

in retracted position with pushpad released.

FINE LATCH ADJUSTMENT

(if needed)

14c.

Top strike fine adjustment: Adjust strike engagement by either retaining or removing shim. Adjust door tightness by moving

insert to desired position. Note that strike pocket can be flipped around to achieve additional adjustment (see step 11).

14d:

TOP LATCH ADJUSTMENT:

With latches extended, turn CCW until the top latchbolt projection begins to visually

decrease, then turn CW until latchbolt projects fully. Rotate CW one additional full turn.

Bottom Adjustment

TOP ADJUSTMENT SCREW EXPOSED

ADJUST

with flat blade screwdriver

(PUSH IN & TURN)

Top Adjustment

DEVICE OPERATION TROUBLESHOOTING

Device not latching

when door closes

Latches release, but pushpad

will not fully depress

Latches are not releasing when

pushpad is fully depressed

Bottom bolt is not properly aligned with bottom strike hole.

Top strike insert is not installed or not correctly aligned with

the holdback.

Through fasteners for trim (if applicable) are interfering with

internal centerlift assembly.

Rods improperly adjusted

Device centercase lift finger not inserted properly into

centerlift assembly.

Top adjustment screw is adjusted too far in the retracted

direction (CCW).

Device centercase lift finger not inserted properly into

centerlift assembly.

Top adjustment screw is adjusted too far in the extended

direction (CW).

Bottom adjustment screw is adjusted too far in the extended

direction (CCW).

Modify bottom strike hole for fit.

Install and/or position strike insert per instructions.

Loosen and re-position through screws to clear.

Adjust rods per instructions.

Remove device and re-install per instructions.

Remove device from backplate and re-install with

lift finger correctly inserted.

Rotate top adjustment screw in the extended

direction (CW) per FINE LATCH ADJUSTMENT

procedure.

Remove device from backplate and re-install with

lift finger correctly inserted.

Rotate top adjustment screw in the retracted

direction (CCW) per FINE LATCH ADJUSTMENT

procedure.

Rotate bottom adjustment screw in the retracted

direction (CW) per FINE LATCH ADJUSTMENT

procedure.

SOLUTION

POSSIBLE CAUSE

SYMPTOM

BOTTOM ADJUSTMENT SCREW EXPOSED

ADJUST

with flat blade screwdriver

(PUSH IN AND TURN)

EXTEND BOLT (CCW)

RETRACT BOLT (CW)

14e:

BOTTOM LATCH ADJUSTMENT:

With pushpad depressed (retracted position),

extend or retract bottom bolt to desired engagement and clearance.

14f.

Check device operation. Reference STEP 14a & 14b.

14d

14e

LATCH IN

EXTENDED

POSITION

LATCH IN

RETRACTED

POSITION

CAUTION:

If turned too far CW,

you will lose sight

of adjustment screw

EXTEND BOLT (CW)

RETRACT BOLT (CCW)