10

F

D

Fig. 10

g

Fig. 11

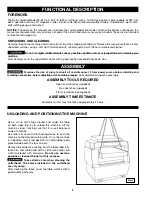

TABLE ADJUSTINg CONTROLS

To reduce the risk of injury, turn unit off

and disconnect it from power source before installing

and removing accessories, before adjusting or when

making repairs.

An accidental start-up can cause injury.

Thickness settings to accomodate thick or thin

workpieces can be fast and easy. Turn the machine

"ON"

and engage the feed rolls, then raise or lower

the table by pulling up or pushing down on the table-

adjusting control lever (C) Fig. 10.

You can fine adjust the table height by loosening the

lock knob (D) Fig. 10 and turning the table-adjusting

handwheel (E). Tighten the lock knob (D) after adjusting.

NOTE:

The English/Metric Scale (F) indicates table

height setting.

Use the English/Metric scale and shelf (G) Fig. 11,

located on the front of the table, to determine the

thickness of stock, before or after planing, by placing

the stock on the shelf as shown in Fig. 11. This enables

you to quickly position the table for the next cut.

NOTE:

Raise the table to its final position rather than

lowering it to ensure a stable, accurate setting.

C

E

OPERATION

OPERATIONAL CONTROLS AND ADJUSTMENTS

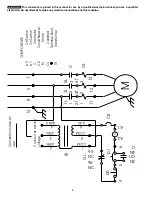

Start the machine by pressing the green (shrouded)

"ON"

button (A) Fig. 9. Stop the machine by pressing

the red (mushroom type)

"OFF"

button (B) Fig. 9.

B

A

Fig. 9

STARTINg AND STOPPINg THE PLANER

To reduce the risk of injury, turn unit off and disconnect it from power source before installing and

removing accessories, before adjusting or when making repairs.

An accidental start-up can cause injury.

Содержание 22-610

Страница 63: ...63 NOTES NOTAS ...