115.6031.0

- 36 -

TABLE 4-1 TROUBLESHOOTING CHART

PROBLEM

PROBABLE CAUSE

CORRECTIVE ACTION

Unable to maintain evaporator

capacity.

1. Vaporizer chamber fouled, dirty or

filled with deposits, reducing

chamber capacity.

2. Tank car padding pressure high

1. Disassemble the evaporator and

clean as necessary.

2. Decrease padding pressure to

recommended levels. Increase heat

setting on temperature controller

within recommended settings.

Frost or sweating visible on the

pressure reducing valve (PRV)

and/or the adjacent piping.

1. Superheat temperature setting not

properly set for the maximum

feeder feed rate.

2. With proper superheat setting at

maximum feed rate, the chamber

capacity has been compromised

by collected impurities.

3. The PRV is mounted too far away

from the Vaporizer and the super

heat value is being lost allowing

liquefaction of the gas.

1. Refer to section 3.7 - Placing In

Operation and readjust temperature

setting accordingly.

2.Shut down the Vaporizer as described

under Section 3.10, disassemble the

vaporizer and clean as necessary.

3.Insulate the piping between the

Vaporizer and PRV. Heat trace the

piping between the Vaporizer and the

PRV. Move the PRV closer to the

Vaporizer slopping the piping towards

the Vaporizer.

When the vaporization

chamber was pulled for the

routine service, it was noted

to have corrosion and the

cathodic protection anodes

did not show signs of being

consumed. The cathodic

protection green light was on

during vaporizer operation.

1. Either the anode wiring or the

anodes had a direct path to

electrical ground.

1. When replacing the serviced

chamber in the water bath, be sure

that the insulating grommets are in

place and that the anode wiring is

correct. Exercise care when

replacing the chamber back into the

water jacket to avoid dislodging the

anodes from their bracket. After the

vaporizer chamber is returned to the

dry water bath chamber, power the

controls without heater power applied.

If the green light is on check the

cathodic protection circuitry for

connection to ground.

Содержание Capital Controls 71V3B Series

Страница 1: ... 1 115 6031 0 Instruction Manual Series 71V3B Electrically Heated Vaporizer CAPITAL CONTROLS ...

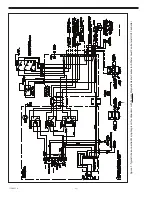

Страница 9: ... 9 115 6031 0 Figure 1 Sectional Diagram ...

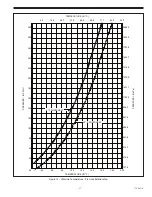

Страница 17: ... 17 115 6031 0 Figure 4 Outline Mounting Dimensions 12 kW 15 kW Heaters ...

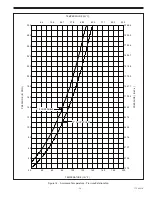

Страница 18: ...115 6031 0 18 Figure 5 Outline Mounting Dimensions 18 kW Heater ...

Страница 42: ...115 6031 0 42 PAGE INTENTIALLY LEFT BLANK ...