5

2.5 FALL

CLEARANCE:

Ensure suf

fi

cient clearance exists in your fall path to prevent striking an object during

a fall. The clearance required is dependent upon the subsystem (rope grab and lanyard, rope grab and

carabiner) and lifeline properties. Table 1 shows the approximate elongation for new DBI/SALA lifelines in

dry conditions. The elongation speci

fi

ed is for an applied static load of 1,800 lbs (8 kN). Lifeline elongation

must be considered when estimating fall clearance. Factors that affect fall clearance include:

•

Elevation of anchorage

•

Free fall distance

•

Worker height

•

Connecting subsystem length

•

Lifeline elongation. See Table 1:

•

Deceleration distance

•

Movement of harness attachment element

Table 1 - Life Line Elongation: ft (m)

Lifeline Type

Lifeline Lenght: ft (m)

25 (8) - 75 (23)

100 (30)

150 (46)

3/8” Wire Rope

—

0.43 (0.13)

0.65 (0.2)

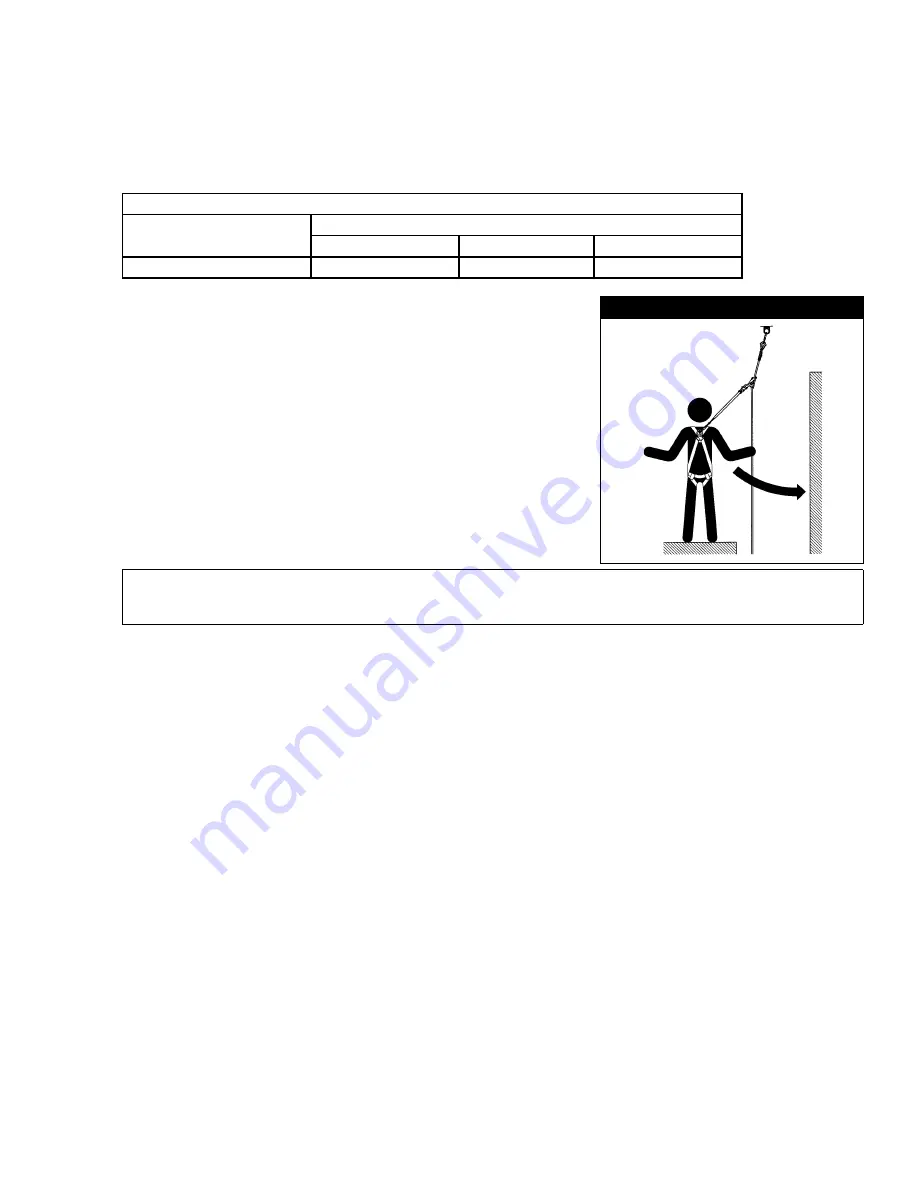

2.6 SWING

FALLS:

Swing Falls occur when the anchorage point is

not directly above the point where a fall occurs (see Figure 4).

The force of striking an object in a swing fall may cause serious

injury or death. Minimize swing falls by working as close to the

anchorage point as possible. Do not permit a swing fall if injury

could occur. Swing falls will signi

fi

cantly increase the clearance

required when a SRL (self-retracting lifeline) or other variable

length connecting subsystem is used.

2.7 ENVIRONMENTAL

HAZARDS:

Use of this equipment in areas

with environmental hazards may require additional precautions

to prevent injury to the user or damage to the equipment.

Hazards may include, but are not limited to; heat, chemicals,

corrosive environments, high voltage power lines, gases, moving

machinery, and sharp edges.

Figure 4 – Swing Falls

Swing Fall Hazard

WARNING:

When working with tools, materials, or in high temperature environments, ensure that

associated fall protection equipment can withstand high temperatures, or provide protection for those

items.

2.8 COMPATIBILITY OF COMPONENTS:

Capital Safety equipment is designed for use with Capital Safety

approved components and subsystems only. Substitutions or replacements made with non-approved

components or subsystems may jeopardize compatibility of equipment and may effect the safety and

reliability of the complete system.

2.9 COMPATIBILITY OF CONNECTORS:

Connectors are considered to be compatible with connecting

elements when they have been designed to work together in such a way that their sizes and shapes do not

cause their gate mechanisms to inadvertently open regardless of how they become oriented. Contact Capital

Safety if you have any questions about compatibility.

Connectors (hooks, carabiners, and D-rings) must be capable of supporting at least 5,000 lbs (22.2 kN).

Connectors must be compatible with the anchorage or other system components. Do not use equipment

that is not compatible. Non-compatible connectors may unintentionally disengage (see Figure 5). Connectors

must be compatible in size, shape, and strength. If the connecting element to which a snap hook (shown) or

carabiner attaches is undersized or irregular in shape, a situation could occur where the connecting element

applies a force to the gate of the snap hook or carabiner. This force may cause the gate (of either a self-

locking or a non-locking snap hook) to open, allowing the snap hook or carabiner to disengage from the

connecting point. Self- locking snap hooks and carabiners are required.

Содержание LAD-SAF 5000338

Страница 2: ...2 ...

Страница 10: ...10 8 0 LABELING This Identification Label must be present and completely legible ...