150i Desktop Card Personalization System

21

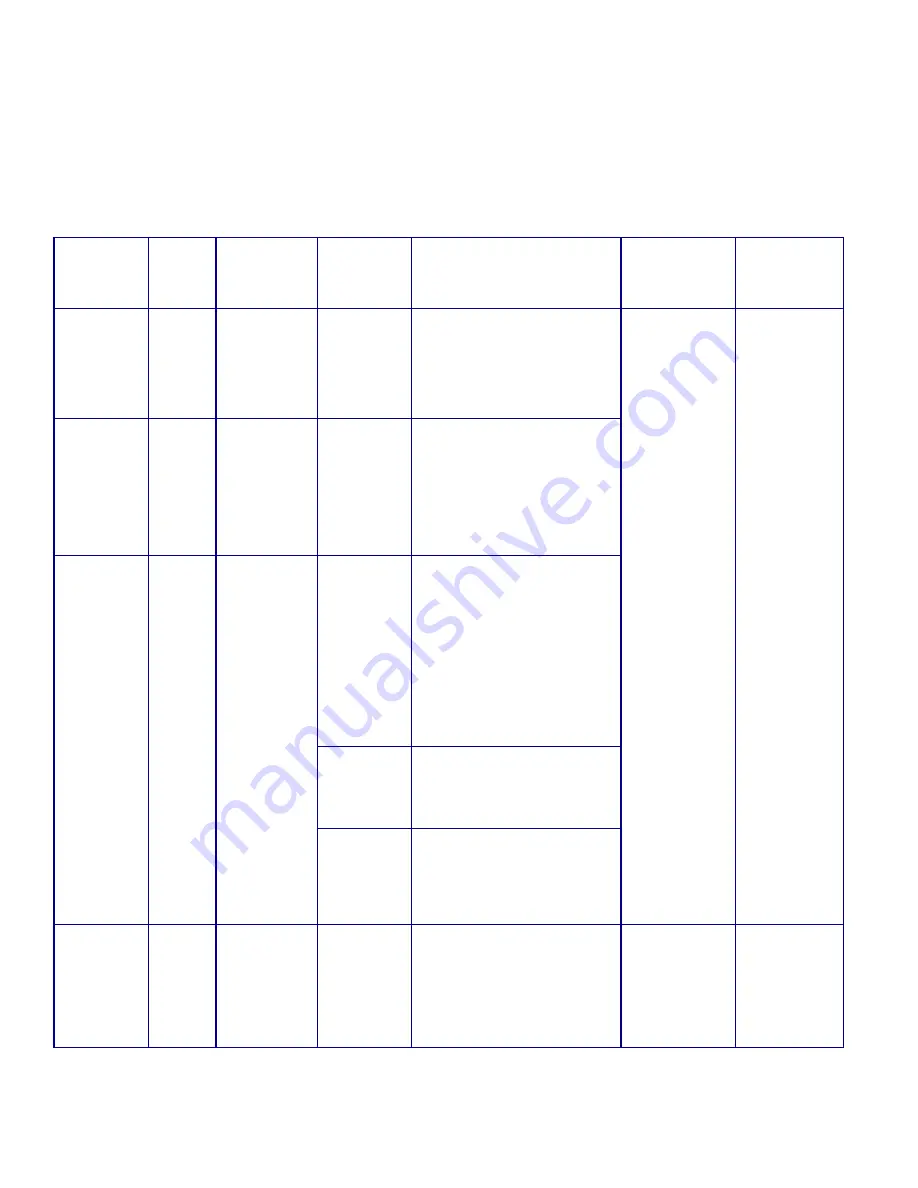

General System Errors

When a general system error occurs, a status code is sent to the application based

on what type of error is happening. Call for service if the specified corrective

action does not resolve the problem.

Error

Message

(LCD)

Error

Code

(LCD)

Meaning

Possible

Cause

Corrective Action

(Operator)

Status Code

Sent to

Application

Card

Processing

Status

Transport

Error

XXYY01

XXYY02

XXYY03

XXYY04

The card

carriage could

not verify its

left-to-right

position.

Loose card in

system

Open the top cover and verify no

obstructions (such as cards)

prevent the card carriage transport

from moving to the right or left.

Remove any cards that have fallen

inside the system. Try sending the

card again.

Transport

Error

XXYY05

XXYY06

XXYY07

XXYY08

The card

carriage could

not verify its

forward and

back position.

Loose card in

system

Open the top cover and verify that

there are no obstructions to prevent

the card carriage transport from

moving forward or back. Remove all

cards from the input hopper. Check

the input hopper to determine if any

cards are jammed or protruding

from the back. Try sending the card

again.

The input

hopper is

jammed –

gears out of

synch

Remove the weight and all cards

from the input hopper.

Open the output door to gain

access to the input hopper O-ring

belt. Lift up slightly on the bracket

that holds the throat gap motor

(brass colored, at the back of the

input hopper), pull down on the O-

ring belt to move the hopper to

home position. Release the motor

bracket. Reinitialize the system. Try

sending the card data again.

Too many

single cards

inserted

Remove all cards from the input

hopper and remove any jammed or

protruding cards. Reinitialize the

system. Try sending the card data

again.

Transport

Error

XXYY09

XXYY0A

The input

hopper

mechanism

could not find

home position.

Feed error –

cards stuck

together

Remove all cards from the input

hopper and remove any jammed or

protruding cards. Reinitialize the

system. Fan the cards before

loading them to remove the static.

Try sending the card data again.

B = X and Y

Stepper Error

Card moved to

reject tray if

possible

Emboss

Wheel Error

XXYY0B

XXYY0C

The emboss

wheel could not

find home

position.

The

embossing

wheel could

not verify

home position

before

embossing a

card

Try sending the card data again. If

the error repeats, confirm that the

embossing wheel is not jammed

and can spin by turning it manually.

D = Wheel

Stepper Error

Card moved to

reject tray

Содержание 150i

Страница 6: ...vi ...

Страница 23: ...150i Desktop Card Personalization System 17 ...

Страница 24: ...18 Owner s Manual ...