DH-SMT/FI

VI.KA.C4.3C

© Danfoss 09/2009

2

4

4

3

3

2

2

1

1

A

EnGlISh

Safety notes

To avoid injury of persons and damages

to the device, it is absolutely necessary

to carefully read and observe these

instructions.

Necessary assembly, start-up and

maintenance work must only be

performed by qualified and authorized

personnel.

Cleaning the heat exchange plates

Backwash

The backwash removes fouling that has

accumulated on the surface of the plate.

Clean water is flushed with high speed

into the primary and / or secondary side in

the opposite direction from the one used

during normal operation.

The heat exchanger can also be washed

with a cleaning compound, approved

by Danfoss (e.g. Kaloxi® or Radiner FI

liquid cleaner concentrate), which is

environmentally friendly and can be

disposed of through a normal sewer.

After using a cleaning compound,

the heat exchanger must be flushed

thoroughly with fresh water.

Cleaning the heat exchange plates by

hand

You cannot open the brazed heat

exchanger.

Do not damage the heat exchange plates

gasket during cleaning.

Detach the heat exchange plates from the

heat exchanger for cleaning. Clean the

plates with a soft brush and running water.

If the dirt does not come off the plates

easily, you can use a cleaning compound.

After use of the cleaning compound, the

heat exchange plates must be rinsed

completely with clean running water.

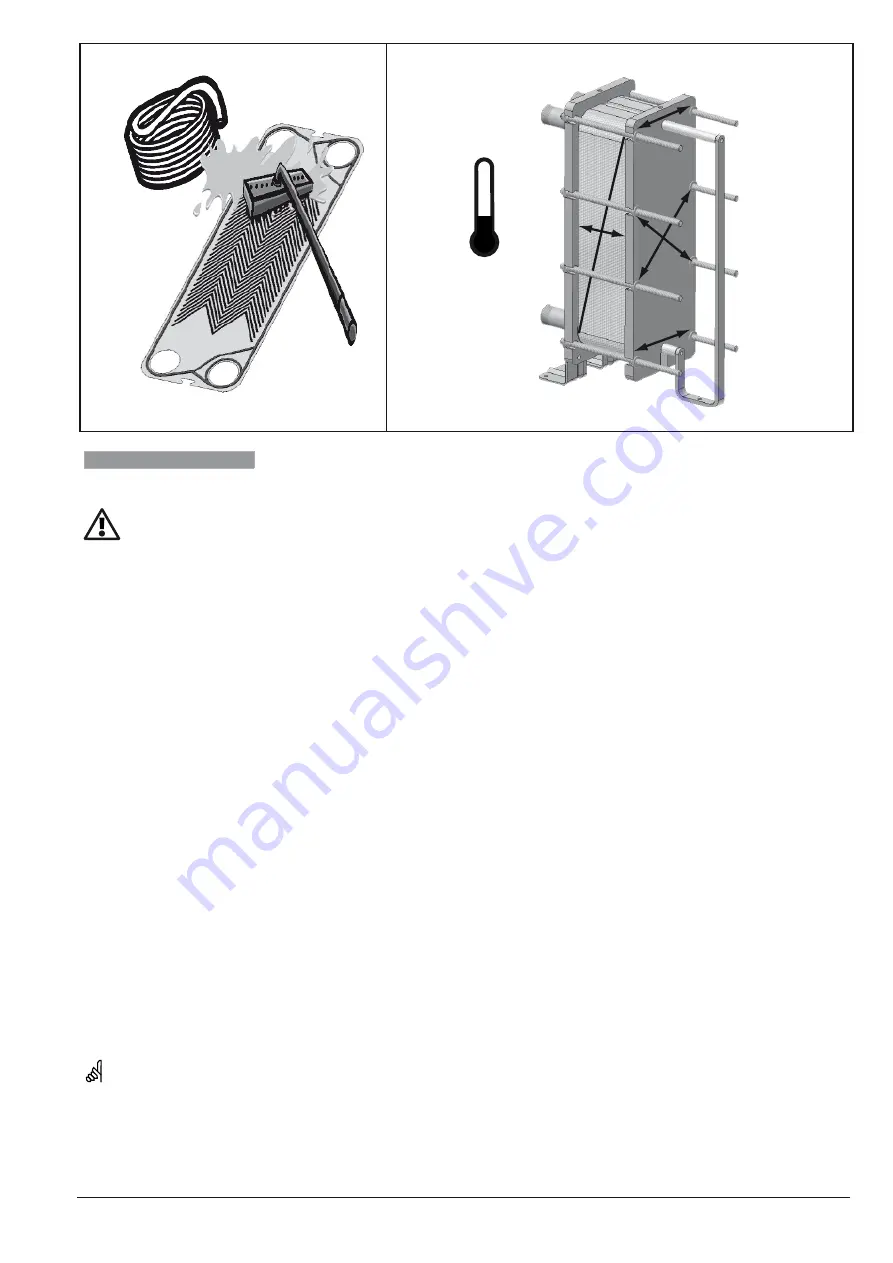

Opening the gasket heat exchanger

Wait for the heat exchanger’s temperature

to fall below +40 °C before opening the

heat exchanger.

1. Drain the heat exchanger.

2. Mark the order of the exchange plates

by drawing a diagonal line to the

exchanger.

3. Measure and note the heat exchanger’s

measurement (tightening measurement

A).

4. Loosen and detach the exchanger’s

tightening bolts.

5. Open the plate pack by moving the end

plate. Detach the heat exchange plates

carefully from each other.

replacement of gaskets XG 10 gaskets

1. Remove the old gasket.

2. Place the new gasket into the groove.

The plate is ready for mounting to the

heat exchanger.

Clip-on gaskets

For XG 14, XG 18, XG 20, XG 31, XG 40,

XG 50.

1. Remove the old gasket.

2. Place the new clip-on gasket into the

groove and fasten it with the aid of the

clip. The plate is ready for mounting to

the heat exchanger.

< +40˚C

Glued gaskets

For XG heat exchangers except for XG-10

and ones equipped with clip-on gaskets

(see sections above).

1. Remove the old gasket.

2. Clean the gasket groove carefully (note

the safety aspects when using e.g.

thriclorethylene).

3. Apply the glue into the gasket groove

and let it dry for about 10 minutes.

4. Place the gasket into the groove an let

it dry for about 1 hour. After drying,

the plate can be mounted to the heat

exchanger.

reassembling the heat exchanger

Before reassembly, check that the sealing

surfaces are clean and the gaskets are

securely attached to the heat exchange

plates.

1. Mount the plates in the opposite order

from that used in dismantling, with the

gasket side of the plate towards the

front end plate.

2. Check that adjacent plate profiles are

in opposite directions (see the plate

diagram).

3. Press the plates against each other and

start the tensioning of the plate back

by tightening the bolts evenly (start

tightening from center to outwards, see

the numbering). Ensure that the end

plates are parallel at all times.

4. Continue tightening until the heat

exchanger’s measurement A (tightening

measurement) is achieved.

5. The tightening measure is correct

when the crests of the plates are in

metal contact with each other. Excess

tightening can cause changes in the

plate profiles.

Содержание XG 14

Страница 16: ...DH SMT FI VI KA C4 3C Danfoss 09 2009 16...