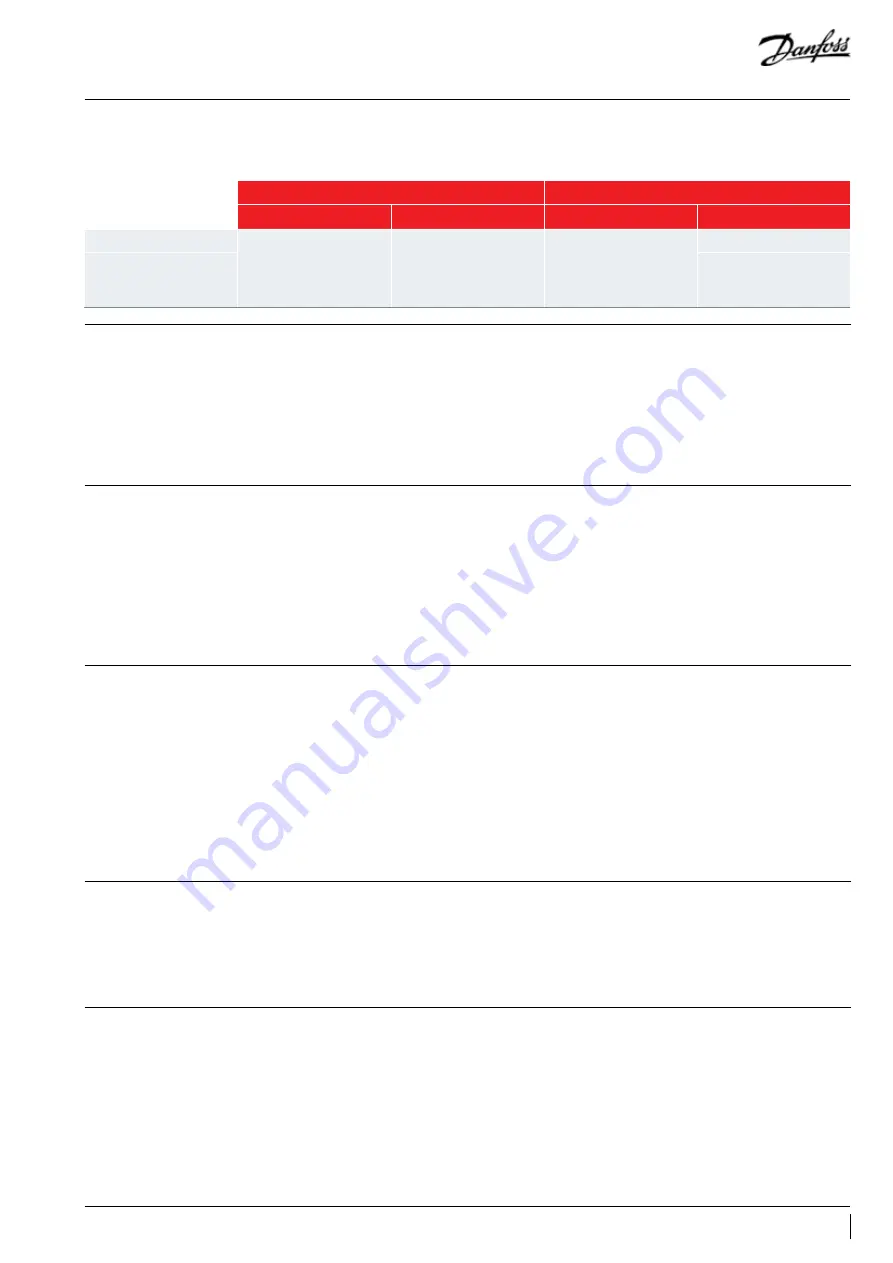

Control logic

Safety control logic

requirements

Tripping conditions

Re-start conditions

Value

Time

Value

Time

HP switch

See Pressure settings table

from section “Manage

operating envelope”

Immediate, no delay.

No by- pass

Conditions back to normal.

Switch closed again

Manual reset

LP safety switch

Maximum 5 auto reset during

a period of 12 hours, then

manual reset.

High pressure

According to EN378-2, a high-pressure (HP) safety

switch is required to shut down the compressor.

The high-pressure switch can be set to lower

values depending on the application and

ambient conditions. The HP switch must either be

placed in a lockout circuit or consist of a manual

reset device to prevent cycling around the

high-pressure limit. If a discharge valve is used,

the HP switch must be connected to the service

valve gauge port, which must not be isolated.

For CDS803 drive, HP switch can be connected to

STO (Safe Torque Off) input 37 or to an external

contactor placed between drive and compressor.

Must remove the jumper (factory supplied)

before connecting HP switch on terminals T37

and T12.

Low pressure

A low-pressure (LP) safety switch must be

used. Deep vacuum operations of a scroll

compressor can cause internal electrical arcing

and scroll instability. VLZ compressors exhibit

high volumetric efficiency and may draw very

low vacuum levels, which could induce such a

problem. The low-pressure switch must be set at

or above “Minimum Low pressure switch setting”.

The switch can be integrated directly in the safety

chain of the compressor or it can be treated by

the unit controller.

If the LP switch is connected to Terminal 27

Digital Input, it is necessary to keep a parameter

of 5.12 to default value “coast inverse” to make

sure LP cut-out has a higher priority than internal

minimum run time function.

Electronic expansion valve

Reverse rotation protection

With variable capacity systems, an electronic

expansion valve (EXV) is the strongly

recommended solution to handle refrigerant

mass flow variations. Danfoss recommends the

use of ETS products. Ramp-up and ramp-down

settings, of both EXV and compressor, must be

done with great care.

Ramp-up of the EXV must be shorter than

the ramp-up of the compressor, to avoid any

low pressure operation on suction side of the

compressor. The EXV can also be opened, up

to a certain degree, before the startup of the

compressor.

Ramp-down of the EXV must be longer than the

ramp-down of the compressor, also to avoid low

pressure operation (except with pump-down).

EXV should be closed, and remain closed,

when the compressor is off, to avoid any liquid

refrigerant entering the compressor.

Due to drive protection, compressors could work

properly even if the power connection between

the drive and mains are dis-matched. However,

the wires between compressor and drive must be

connected accordingly. To protect compressors

from reverse rotation, pressure difference could

be checked as a reference value. Use pressure

sensors to monitor pressure difference between

discharge and suction of the compressor, and for

normal operation, discharge pressure should be

at least 1 bar higher than suction pressure within

30 s running after compressor starting.

Short cycle protection

Short cycling protection requirements need to be

implemented in OEM unit controller:

Meantime, the factory default setting needs to

be disabled( 28-00 short cycle protection change

from default setting “enable” to “disable”).

- 3 minutes minimum running time: in order to

get oil return back from circuit to compressor

sump

- 12 starts maximum per hour: to avoid threaten

the lifetime of motor and other mechanics due

to frequent starts, OEM needs to limit the starts

cycles within 12 times per hour.

- 10s minimum OFF time: to make sure discharge

valve is closed and motor is stopped before next

start, OEM needs to set the minimum off time as

10 seconds.

35

AB444226142054en-000101

Содержание VLZ065

Страница 2: ......

Страница 53: ...53 AB444226142054en 000101...