82 of 132

M-SV-001-EN Rev.E

Compressor Components

Figure 77 - Connecting Leads

to PWM Connector and HV-

Test Point

6. Repeat Step 3 for all 10 pin holes on both PWM

connectors.

7. Still set on diode measurement, place the black

(-) multimeter lead on the HV+ test point of the

Backplane and the red (+) multimeter lead in

the first pin hole of the PWM connector, ensure

the lead makes contact with the clip in the pin

hole. See Figure 78 (Connecting Leads to PWM

Connector and HV+ Test Point). The measured

voltage drop should be 0.39-0.46VDC.

8. Repeat Step 5 for all 10 pin holes of both PWM

connectors.

9. If any of the test results are out of the 0.39 -

0.46 VDC range, the PWM is defective and should

be replaced.

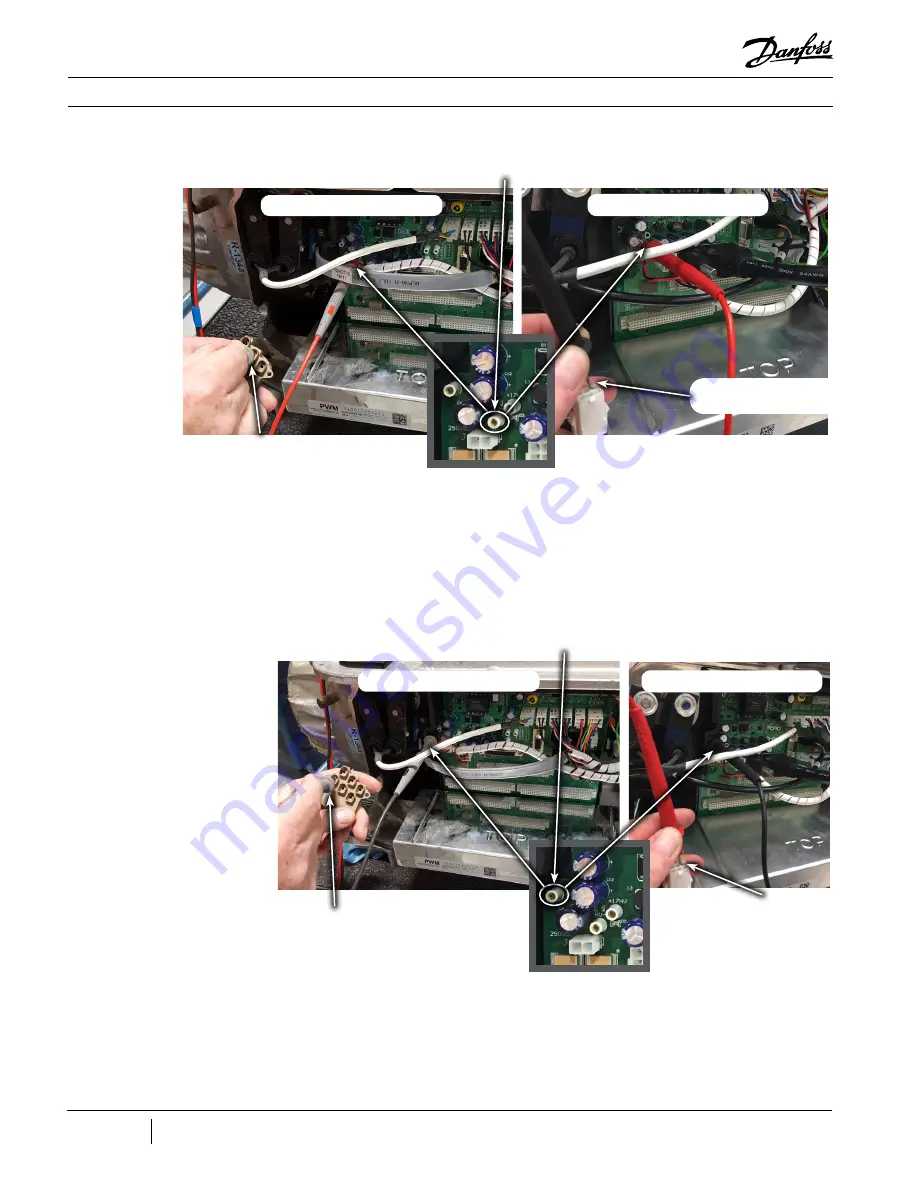

Figure 78 - Connecting Leads

to PWM Connector and HV+

Test Point

Red (+) Lead to HV-

Black (-) Lead to PWM

Molex Connector

Black (-) Lead to PWM

Connector

Red (+) Lead to PWM

Connector

Red (+) Lead to PWM

Molex Connector

Major Revision “E” and Earlier

Major Revision “F” and Later

Black (-) Lead to HV+

Major Revision “E” and Earlier

Major Revision “F” and Later

Содержание Turbocor TG230

Страница 2: ...THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 4: ...4 of 132 M SV 001 EN Rev E THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 12: ...12 of 132 M SV 001 EN Rev E THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 28: ...28 of 132 M SV 001 EN Rev E Compressor Fundamentals Figure 18 Compressor Energy and Control Flow Block Diagram ...

Страница 61: ...61 of 132 M SV 001 EN Rev E Compressor Components Figure 56 Stator Thermistor R T Curve 1 ...

Страница 120: ...120 of 132 M SV 001 EN Rev E THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 130: ...130 of 132 M SV 001 EN Rev E Notes ...