12 Special requirements for R32 units

Installation and operation manual

14

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

Piping requirements

CAUTION

Piping MUST be installed according to instructions given in

30]. Only mechanical joints (e.g.

braze+flare connections) that are compliant with the latest

version of ISO14903 can be used.

Low temperature solder alloys shall not be used for pipe

connections.

For piping installed in the occupied space, make sure that the piping

is protected against accidental damage. Piping should be checked

according to the procedure as mentioned in the installation and

operation manual delivered with the outdoor unit.

12.3

To determine the required safety

measures

Step 1

– Determine the total amount of refrigerant in the system.

See the installation and operation manual delivered with the outdoor

unit.

Step 2

– Determine the area of the room in which the SV unit is

installed:

The room area can be determined by projecting the walls, doors and

partitions to the floor and calculating the enclosed area.

Spaces connected by only false ceilings, ductwork, or similar

connections are not considered a single space.

Step 3

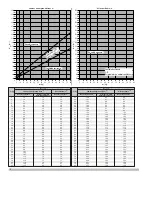

– Use the graphs or tables (see

2] at the

beginning of this manual) to determine the required safety measures

for the SV unit.

m

Total refrigerant charge in the system [kg]

A

min

Minimum room area [m²]

(a)

Lowest underground floor (=Lowest underground floor)

(b)

All other floors (=All other floors)

(c)

No safety measure (=No safety measure)

(d)

External alarm OR Natural ventilation (=External alarm

OR Natural ventilation)

(e)

Ventilated enclosure (=Ventilated enclosure)

(f)

Ventilated enclosure OR External alarm + natural

ventilation (=Ventilated enclosure OR External alarm +

natural ventilation)

Use the total amount of refrigerant in the system and the area of the

room in which the SV unit is installed to check which safety measure

is required.

Note:

When "No safety measure" is required, it is still allowed to

apply natural ventilation or install an external alarm or ventilated

enclosure if wanted. Follow the respective instructions as described

further below.

Note:

When natural ventilation is required, it is still allowed to install

an external alarm or ventilated enclosure if wanted. Follow the

respective instructions as described further below.

Note:

When an external alarm is required as safety measure, it is

also allowed to install a ventilated enclosure. Follow the instructions

described further below.

Use the first graph (Lowest underground floor

(a)

) in case the SV unit

is installed in the lowest underground floor of a building. For other

floors, use the second graph (All other floors

(b)

).

OTHER FLOORS

LOWEST UNDERGROUND FLOOR

The graphs and table are based on an installation height of the SV

unit between 1.8 m and 2.2 m. The installation height is the height of

the bottom of the SV unit to the floor. See also

site requirements of the unit"

23].

If the installation height is more than 2.2 m, different boundaries for

the applicable safety measures can apply. To know which safety

measure is required in case the installation height is more than

2.2 m, refer to the online tool (

).

NOTICE

SV units cannot be installed lower than 1.8 m from the

lowest point of the floor.

Example

The total amount of refrigerant in the VRV system is 20 kg. All SV

units are installed in spaces that do NOT belong to the lowest

underground floor of the building. The space in which the first SV

unit is installed has a room area of 50 m², the space in which the

second SV unit is installed has a room area of 15 m².

▪ Based on the graph for "All other floors" (All other floors), the room

area limit is

40 m²

for No safety measure" (No safety measures).

▪ This means that the following safety measures are required:

SV unit

Room area

Required safety measure

1

A=50 m²≥40 m²

No safety measures

2

A=15 m²<40 m²

Ventilated enclosure OR

External alarm + natural

ventilation

0

10

20

30

40

50

70

90

110

80

60

100

5

10

20

30

40

50

25

15

35

45

m

[kg]

A

min

[m

2

]

No safety measure

(c)

Ventilated enclosure

OR

External alarm + natural ventilation

(f)

m

Total refrigerant charge in the system [kg]

A

min

Minimum room area [m²]

(a)

Lowest underground floor (=Lowest underground floor)

(b)

All other floors (=All other floors)

(c)

No safety measure (=No safety measure)

(d)

External alarm OR Natural ventilation (=External alarm

OR Natural ventilation)

(e)

Ventilated enclosure (=Ventilated enclosure)

(f)

Ventilated enclosure OR External alarm + natural

ventilation (=Ventilated enclosure OR External alarm +

natural ventilation)