5 Before operation

Installation and operation manual

10

SV1ASV4~8A14AJV1B

VRV 5 safety valve unit

4P709466-1 – 2023.09

4.1

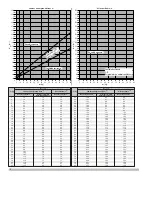

System layout

INFORMATION

The following figure is an example and may NOT

completely match your system layout

a

c

d

e

g

i

f

e

c

c

e

h

i

i

i

b

e

j

a

Heat pump outdoor unit

b

Safety valve unit (SV)

c

VRV direct expansion (DX) indoor unit

d

VRV direct expansion (DX) indoor unit (direct connection

from outdoor to indoor)

e

Remote controller in

normal mode

f

Remote controller in

alarm only mode

g

Remote controller in

supervisor mode

(mandatory in

some situations)

h

Centralised controller (optional)

i

Option PCB (optional)

j

Cool/heat changeover remote control switch (optional)

Refrigerant piping

Interconnection and user interface wiring

Direct connection of indoor units to the outdoor unit

5

Before operation

CAUTION

See

7] to acknowledge all

related safety instructions.

NOTICE

NEVER inspect or service the unit by yourself. Ask a

qualified service person to perform this work.

NOTICE

Turn ON the power 6 hours before operation in order to

have power running to the crankcase heater and to protect

the compressor.

This operation manual is for the following systems with standard

control. Before initiating operation, contact your dealer for the

operation that corresponds to your system type and mark. If your

installation has a customised control system, ask your dealer for the

operation that corresponds to your system.

6

Maintenance and service

6.1

Precautions for maintenance and

service

CAUTION

See

7] to acknowledge all

related safety instructions.

NOTICE

NEVER inspect or service the unit by yourself. Ask a

qualified service person to perform this work.

NOTICE

Maintenance MUST be done by an authorised installer or

service agent.

We recommend performing maintenance at least once a

year. However, applicable legislation might require shorter

maintenance intervals.

Following symbols may occur on the indoor unit:

Symbol

Explanation

Measure the voltage at the terminals of main circuit

capacitors or electrical components before servicing.

6.2

About the refrigerant

CAUTION

See

7] to acknowledge all

related safety instructions.

This product contains fluorinated greenhouse gases. Do NOT vent

gases into the atmosphere.

Refrigerant type: R32

Global warming potential (GWP) value: 675

Periodical inspections for refrigerant leaks may be required

depending on the applicable legislation. Contact your installer for

more information.

NOTICE

Applicable legislation on

fluorinated greenhouse gases

requires that the refrigerant charge of the unit is indicated

both in weight and CO

2

equivalent.

Formula to calculate the quantity in CO

2

equivalent

tonnes:

GWP value of the refrigerant × total refrigerant

charge [in kg]/1000

Contact your installer for more information.

6.2.1

About the refrigerant leakage sensor

WARNING

The R32 refrigerant leakage sensor must be replaced after

every detection or at the end of its lifetime. ONLY

authorised persons may replace the sensor.

NOTICE

The R32 refrigerant leakage sensor is a semiconductor

detector which may incorrectly detect substances other

than R32 refrigerant. Avoid using chemical substances

(e.g. organic solvents, hair spray, paint) in high

concentrations, in the close proximity of the SV unit

because this may cause misdetection by the R32

refrigerant leakage sensor.

NOTICE

Functionality of the safety measures are periodically

automatically checked. In case of malfunction, an error

code will be displayed on the user interface.

INFORMATION

The sensor has a lifetime of 10 years. The user interface

displays error "

CH-22

" 6 months before the end of the

sensor lifetime and error "

CH-23

" after the end of the

sensor lifetime. For more information, see the reference

guide of the user interface and contact your dealer.