12

English

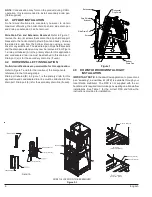

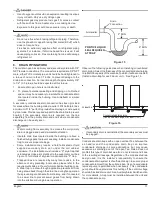

Drain piping connection

Do not connect drain piping directly to sewage pipes where

ammonia odor may be present. Ammonia in the sewage

pipes may enter the indoor unit body through the drain piping

and corrode the heat exchanger.

NOTE: After piping work is finished, check drainage flows

smoothly.

NOTE: Gradually insert approximately 1 quart of water into the

drain pan to check drainage.

IMPORTANT NOTE:

The evaporator coil is fabricated with oils

that may dissolve styrofoam and certain types of plastics.

Therefore, a removal pump or float switch must not contain any

of these materials.

7.

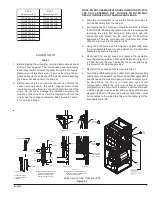

DUCT WORK

This air handler is designed for a complete supply and return

ductwork system. To ensure correct system performance, the

ductwork is to be sized to accommodate 350-450 CFM per ton

of cooling with the static pressure not to exceed 0.9" in w.c.

Refer to ACCA Manual D, Manual S and Manual RS for

information on duct sizing and application. Flame retardant

ductwork is to be used and sealed to the unit in a manner that

will prevent leakage.

•

A downflow application with electric heat must have an L-

shaped sheet metal supply duct without any outlets or

registers located directly below the heater.

7.1

RETURN DUCTWORK

Do not locate the return ductwork in an area that can

introduce toxic or objectionable fumes/odors into the

ductwork.

The return ductwork is to be connected to the air

handler bottom (upflow configuration).

8.

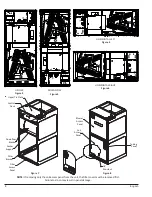

ELECTRICAL WIRING WORK

IMPORTANT:

All routing of electrical wiring must be made

through provided electrical knockouts. When removing the

electrical knockouts, take care not to damage the PCB. Do not

cut, puncture or alter the cabinet for electrical wiring.

8.1

GENERAL INSTRUCTIONS

•

Shut off the power before doing any work.

•

All field supplied parts and materials, electric works must

conform to local codes.

•

Use copper wire only.

•

See also the “Wiring Diagram Label” located inside the unit’s

fan housing.

•

For details on hooking up the remote controller, refer to the

“Remote Controller Installation Manual”.

•

All wiring must be performed by an authorized electrician.

•

Install a wiring interrupter or ground-fault circuit interrupter

for the power wiring.

•

To avoid short circuiting the power supply wire, be sure to

use insulated terminals.

•

Do not turn on the power supply (wiring interrupter or ground-

fault circuit interrupter) until all other work is done.

•

Do not ground units to water piping, telephone wires or

lightning rods because incomplete grounding could cause a

severe shock hazard resulting in severe injury or death, not

to gas piping because a gas leak could result in an explosion

which could lead to severe injury or death.

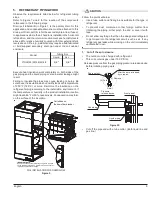

8.2

WIRE SIZING

Wire size is important to the operation of your equipment. Use

the following check list when selecting the appropriate wire

size for your unit.

•

Wire used must be sized to carry the Minimum Circuit

Ampacity (MCA) listed on the equipment’s Rating Plate.

•

Refer to the NEC (USA) or CSA (Canada) for wire sizing.

The unit MCA for the air handler and the optional electric

heat kit can be found on the unit Series and Rating Plate.

•

Wire must be sized to allow no more than a 2% voltage

drop from the building breaker/fuse panel to the unit.

•

Wires with different insulation temperature rating have varying

ampacities - be sure to check the temperature rating used.

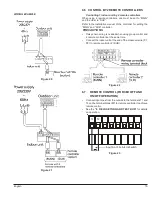

Field Fuses

Size

Wire

Size

15A

Must comply

with

local codes

2-conductor,

stranded,

non-shielded copper/

PVC or vinyl jacket

AWG

18-16

Power Supply Wiring

(Including ground wire)

Transmission Wiring

Remote Controller Wiring

Outdoor uni t - I ndoor uni t

Ma x. 3280 ft.

(Tota l wi ri ng l e gnth: 6560 ft.)

Indoor uni t -Re mote control l e r

Ma x. 1640 ft.

Length of the Transmission Wiring

and Remote Controller Wiring

8.3

SAFETY DEVICE

Every installation must include an NEC (USA) or CEC (Canada)

approved overcurrent protection device. Also, check with local

or state codes for any special regional requirements.

Protection can be in the form of fusing or HACR style circuit

breakers. The Series and Rating Plate provides the maximum

overcurrent device permissible.

When using residual current operated circuit breakers, be sure

to use a high-speed type (0.1 second or less) 30mA rated residual

operating current.

NOTE:

Fuses or circuit breakers are to be sized larger than the

equipment MCA but not to exceed the MOP.

Содержание SkyAir FTQ18TAVJUA

Страница 22: ...22 English THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 23: ...23 English THIS PAGE LEFT INTENTIONALLY BLANK...