17

English

9.2

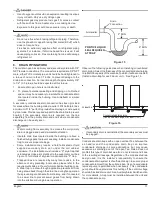

REMOTE CONTROL SETTING (T1, T2)

Forced off and ON/OFF operation should be selected by selecting

the SECOND CODE NO. as shown in Table 5.

External ON/OFF

input

Mode

No.

FIRST

CODE NO.

SECOND

CODE NO.

Forced Off

01*

ON/OFF Operation

02

System/Equipment Protection

03

12/(22)

1

* Factory Set

Table 5

Input A of forced off and ON/OFF operation work as shown in

Table 6.

Forced Off

ON/OFF Operation

System/

Equipment

Protection

Input A "on" to force a stop

(remote controller

reception prohibited)

Unit operated by changing

input A from "off" to "on"

Input A "off" to allow

remote controller

Unit stopped by changing

input A from "on" to "off"

Input A

"off"

to stop

system

Table 6

9.3

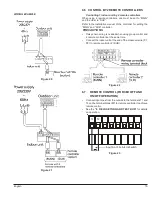

SETTING THE FILTER SIGN DISPLAY

INTERVAL

•

Explain the following to the customer if the filter dirt settings

have been changed.

•

The filter sign display time is set to 2500 hours (equivalent

to 1 year’s use) when shipped.

•

The settings can be changed to not display.

•

When installing the unit in a dusty place, set the filter sign

display time to shorter intervals (1,250 hours).

•

Explain to the customer that the filter needs to be cleaned

regularly to prevent clogging and also the time that is set.

01

02

0

low

high

10000/

5000

ON

OFF

Mode

No.

10 (20)

FIRST CODE NO.

SECOND CODE

NO.

Filter dirt

1 (low/high)

3

Displayed time

(units: hours)

Filter sign

display

2500/

1250

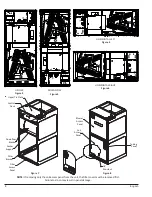

9.4

RETURN AIR FILTER

Each installation must include a return air filter. This filtering may

be performed at the air handler using the factory filter rails or

externally such as a return air filter grille. When using the factory

filter rails, a nominal 16x20x1", 20x20x1" or 24x20x1" (actual

dimension must be less than 23-½”x20") filter can be installed.

Washable versions are available through your local Daikin

distributor.

•

Do not operate this product without all the ductwork attached.

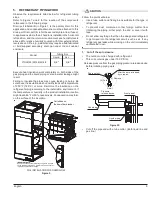

9.5

ELECTRIC HEAT

Refer to the installation manual provided with the electric heat

kit for the correct installation procedure. All electric heat must be

field installed. If installing this option, the ONLY heat kits that

are permitted to be used are the Daikin produced HKS series.

Refer to the air handler unit’s Serial and Rating plate or the HKS

specification sheets to determine the heat kits compatible with a

given air handler. No other accessory heat kit besides the HKS

series may be installed in these air handlers. The heating mode

temperature rise is dependent upon the system airflow, the supply

voltage, and the heat kit size (kW) selected.

Содержание SkyAir FTQ18TAVJUA

Страница 22: ...22 English THIS PAGE LEFT INTENTIONALLY BLANK...

Страница 23: ...23 English THIS PAGE LEFT INTENTIONALLY BLANK...