55

General information on cleaning procedures

Read the safety instructions at the beginning of this manual and page. 53

You should consult with your supplier of chemical products to choose the most suitable for clean-

ing the unit components.

For the cleaning method refer to the instructions of the detergent manufacturer and carefully

read the safety data sheet (SDS).

As general guidelines, refer to the following rules:

• Always use personal protection (safety shoes, safety glasses, gloves, etc.).

• Use mild products (pH between 8 and 9) for washing and disinfecting, in normal concentrations. De-

tergents must not be toxic, corrosive, flammable or abrasive.

• Use a soft cloth or bristle brushes that do not damage the stainless steel surfaces.

• If you use water jets, the pressure should be less than 1.5 bar and the temperature must not exceed 80°C.

• For cleaning components like motors, damper motors, bearings, pitot tubes, filters and electronic sen-

sors (if applicable), do not spray water directly on them.

• After cleaning make sure that you have not damaged the electrical parts and the seals.

• Cleaning operations should not involve the lubricated parts, like rotation shafts, because this could

affect their good operation and create problems with durability.

• For the cleaning of finned components or dampers use an industrial vacuum cleaner and/or a com-

pressor. Attention, the compressed air flow must run opposite to the direction of the airflow through

the unit and parallel to the fins.

Cleaning filters

The machine must NOT be running when the filters are removed to avoid drawing in outside air

that might be contaminated.

The

filters must be cleaned often and carefully to prevent dust and microbial build-up. Usually, compact

filters can be cleaned

two

or three times

(replacement is anyway recommended in preference to wash-

ing) before they are replaced. As a general rule, replacement is required after 500-2000 hours of operation

(it varies depending on the type of filter, refer to the directions of the Manufacturer), but may need to be

replaced much sooner if required.

Compact filters

can be cleaned using a vacuum cleaner or by blowing with compressed air or hot water

(not under pressure).

Pocket filters

cannot be cleaned and must be changed after their life cycle.

Cleaning lamellar components

Remove the dust and fibres with a soft bristle brush or a vacuum cleaner.

Be careful when cleaning with compressed air because the exchanger package can be damaged.

CLEANING with pressure jets is allowed if the maximum water pressure is 3 bar and a flat nozzle

is used (40° - WEG 40/04 type).

Oils, solvents, etc. can be removed with water or hot grease solvents, by washing or immersion.

Periodically clean the condensate drain tray and fill the drain siphon with water.

Содержание Modular Rotary

Страница 15: ...15 Notes...

Страница 28: ...28 Notes...

Страница 33: ...33 VDI 6022 6...

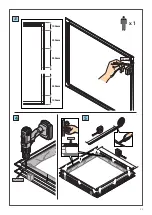

Страница 34: ...34 1 x TE8x35 1 x 8 5 1 x M8 2 x TE8x35 2 x 8 5 2 x M8 7...

Страница 43: ...43 3 4 5 x 1 100mm 100mm 250mm 250mm 250mm 10 100mm 5mm...

Страница 44: ...44 6 7 NO OK...

Страница 45: ...45 H2O SOAP 8...

Страница 46: ...46 9...

Страница 47: ...47 Notes...

Страница 62: ...62 Repair log DATE SERVICE TYPE TIME REQUIRED SIGNATURE...