12

Nameplate Voltage -

That voltage assigned to a piece of

equipment for the purpose of designating its voltage class

and for the purpose of defining the minimum and maximum

voltage at which the equipment will operate.

Utilization Voltage -

The voltage of the line terminals

of the equipment at which the equipment must give fully

satisfactory performance. Once it is established that supply

voltage will be maintained within the utilization range under

all system conditions, check and calculate if an unbalanced

condition exists between phases. Calculate percent voltage

unbalance as follows:

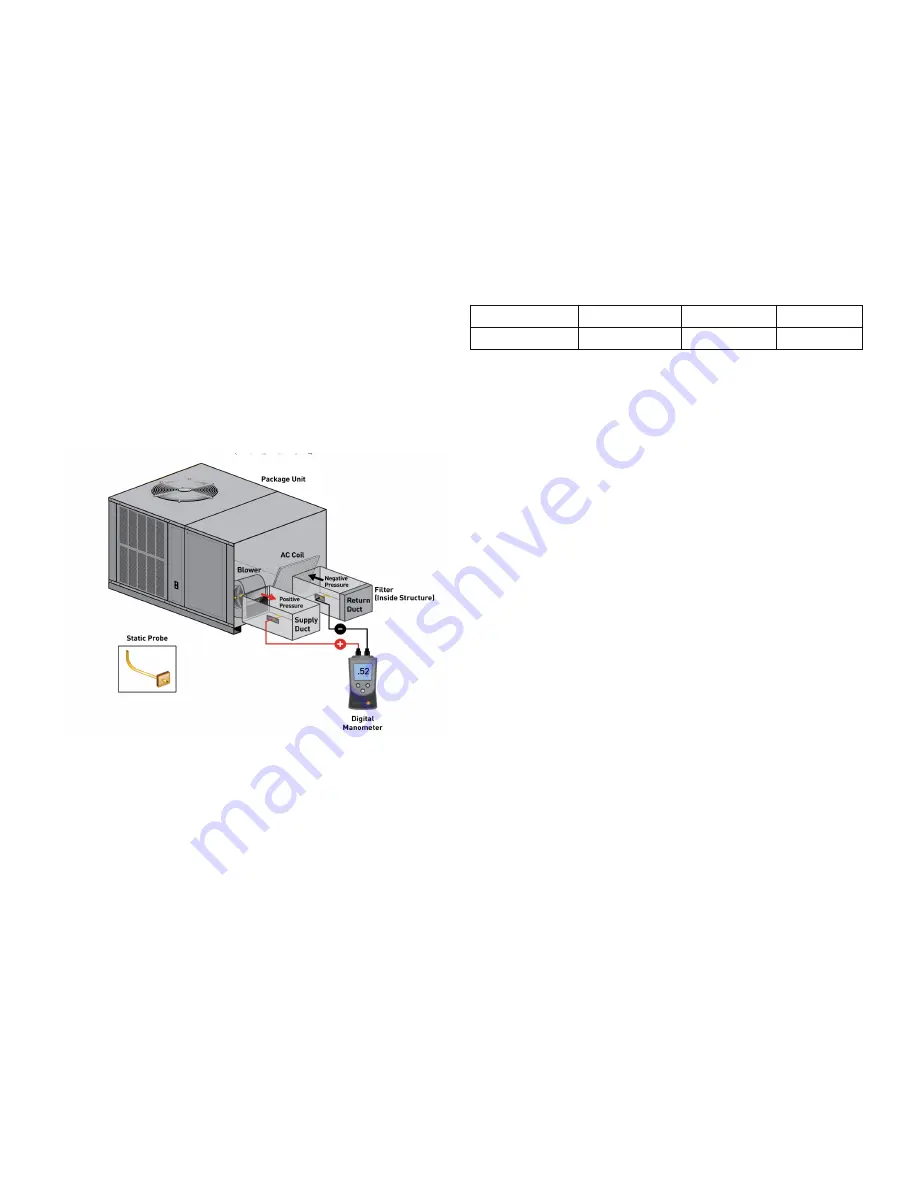

TOTAL EXTERNAL STATIC PRESSURE

CHECK

The total external static pressure must be checked on this

unit to determine if the airflow is proper.

Total External Static Testing

1.

Using a digital manometer measure the static

pressure of the return duct at the inlet of the unit

(Negative Pressure).

Total External Static

2.

Measure the static pressure of the supply duct

(Positive Pressure).

3. Add the two readings together

NOTE: Both readings may be taken simultaneously

and read directly on the manometer if so desired.

4. Consult proper table for quantity of air.

If the external static pressure exceeds the minimum or

maximum allowable statics, check for closed dampers, dirty

filter, undersized or poorly laid out ductwork.

AIR FLOW ADJUSTMENTS

When the final adjustments are complete, the current

draw of the motor should be checked and compared to

the full load current rating of the motor. The amperage

must not exceed the service factor stamped on the motor

nameplate.

If an economizer is installed, check the unit operating

balance with the economizer at full outside air and at

minimum outside air.

High stage airflow setting to be between 300 and 500

CFM per ton, see Table below. For models with electric

heat the total airflow must not be less than that required

for operation of the electric heaters. See Appendix D for

minimum airflow for specific electric heaters.

NOTE: Never run CFM below 300 CFM per ton,

evaporator freezing or poor unit performance is

possible.

Model

Minimum

Maximum

GPHM56041

1500

1850

2500

Nominal

High Stage Airflow Setting, CFM

(without electric heat)

EEM - Standard Static Drive Motor

Adjust the CFM for the unit by changing the position of

the low voltage leads on the terminal block TB1. Refer to

Appendix A for blower performance at each speed tap

NOTE: If more than one lead is energized

simultaneously, the motor will run at the higher

speed.

Fan speed for G (Fan), Y1 (Low Cool) and W1 (Low Heat)

are fixed setting on TB1/T1 and cannot be moved.

Purple wire Y2 (High Cool) and Brown wire W2 (High Heat)

are connected to TB1/T2. These wires can be moved

together or separately and placed on any unoccupied

terminal T3-T5.

Note: for proper operation Y2 and W2 should have a higher

speed setting than the G, Y1 and W1 speed setting.

If Electric Heater kit is installed use the red wire provided

with the literature kit to jumper terminal TB1/W1 to an

unoccupied speed tap that satisfies the minimum airflow

required for the heater kit. This must be a different tap

than Y2 is connected to. Refer to Appendix D for minimum

required airflow for electric heaters.

Note: On Heat Pump units, the Yellow (YL) wire

from relay BR1 to TB1/T2 must always be moved

to the same terminal location as the Brown (BR)

wire after adjustments are made, to ensure

proper blower speed during defrost operation.

SUPERHEAT AND SUBCOOLING

Checking Subcooling

NOTE: Units with a TXV should be charged to

Subcooling only.

EXAMPLE:

a. Liquid Line Pressure = 417 PSI

b. Corresponding Temp. = 120°F

c. Thermometer on Liquid line = 109°F.

Содержание M Series

Страница 18: ...18 Wiring Example Electric Heat Wiring Example...

Страница 25: ...25 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 26: ...26 THIS PAGE INTENTIONALLY LEFT BLANK...

Страница 27: ...27 THIS PAGE INTENTIONALLY LEFT BLANK...