32

S-303 Induced Draft Blower Motor

WARNING

HIGH VOLTAGE

Disconnect ALL power before servicing or in

-

stalling this unit. Multiple power sources may

be present. Failure to do so may cause proper

-

ty damage, personal injury or death.

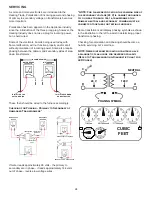

1. Remove burner compartment door to gain access to

the induced draft blower motor.

2. Disconnect the motor wire leads from its connection

point at the induced draft motor.

3. Using a ohmmeter, test for continuity between each of

the motor leads.

4. Touch one probe of the ohmmeter to the motor frame

(ground) and the other probe in turn to each lead

If the windings do not test continuous or a reading is

obtained to ground, replace the motor.

5. If the windings have a continuity reading, reconnect

wires. Turn power on to the furnace and turn the

thermostat on in the heating mode. Check voltage for

115V at the induced draft motor terminals during the

trial for ignition. If you have 115V and the motor does

not run, replace the induced draft motor.

6. After completing check and/or replacement of induced

draft motor, reinstall burner compartment door.

7. Turn on electrical power and verify proper unit

operation.

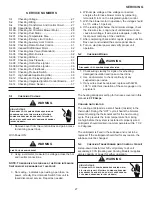

S-304 Checking Gas Valve (Redundant)

A combination redundant operator type gas valve which

provides all manual and automatic control functions

required for gas fired heating equipment is used.

The valve provides control of main burner gas flow,

pressure regulation, and 100 percent safety shut-off.

WARNING

Disconnect ALL power before servicing.

Single stage gas valves should be tested on the furnace

with 24 VAC connected to the gas valve and manometers

reading supply line and manifold pressures.

S-305 Checking Main Burners

Burners have been redesigned for 34.5” chassis furnaces.

Overall length and width dimensions remain the same as

40” model burners. The burners used 34.5” models have

burner head insert with larger diameter center hole and a

larger number of surrounding holes.

The main burners are used to provide complete

combustion of various fuels in a limited space, and transfer

this heat of the burning process to the heat exchanger.

Proper ignition, combustion, and extinction are primarily

due to burner design, orifice sizing, gas pressure, primary

and secondary air, vent and proper seating of burners.

Beckett Burner

WARNING

Disconnect ALL power before servicing.

In checking main burners, look for signs of rust, oversized

and undersized carry over ports restricted with foreign

material, etc, burner cross-over slots should not be altered

in size.

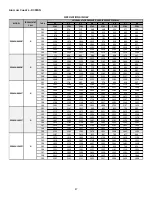

S-306 Checking Orifices

S model furnaces have factory installed #43 natural gas

orifices.

The only time resizing is required is when a reduction in

firing rate is required for an increase in altitude or a furnace

is being converted for use with LP gas.

Orifices should be treated with care in order to prevent

damage. They should be removed and installed with a box-

end wrench in order to prevent distortion. In no instance

should an orifice be peened over and redrilled. This will

change the angle or deflection of the vacuum effect or

entraining of primary air, which will make it difficult to adjust

the flame properly. This same problem can occur if an

orifice spud of a different length is substituted.

SERVICING