PRODUCT DESIGN

33

8. Select the desired “heating” speed tap by positioning

switches S4- 3, 4 appropriately. Refer to figure above.

Verify CFM by noting the number displayed on the dual

7-segment LED display.

In general lower heating speeds will: reduce electrical con-

sumption, lower operating sound levels of the blower, and

increase the outlet air temperature delivered to the home.

The speeds available allow the blower performance to be

optimized for the particular homeowner’s needs.

3

4

A

OFF

OFF

B *

ON

OFF

C

OFF

ON

D

ON

ON

(*Indicates factory s etting)

Sw itch Ba nk: S4

Heating

CFM

DIP S witch No.

PCBKF103 / PCBKF104 / PCBKF105

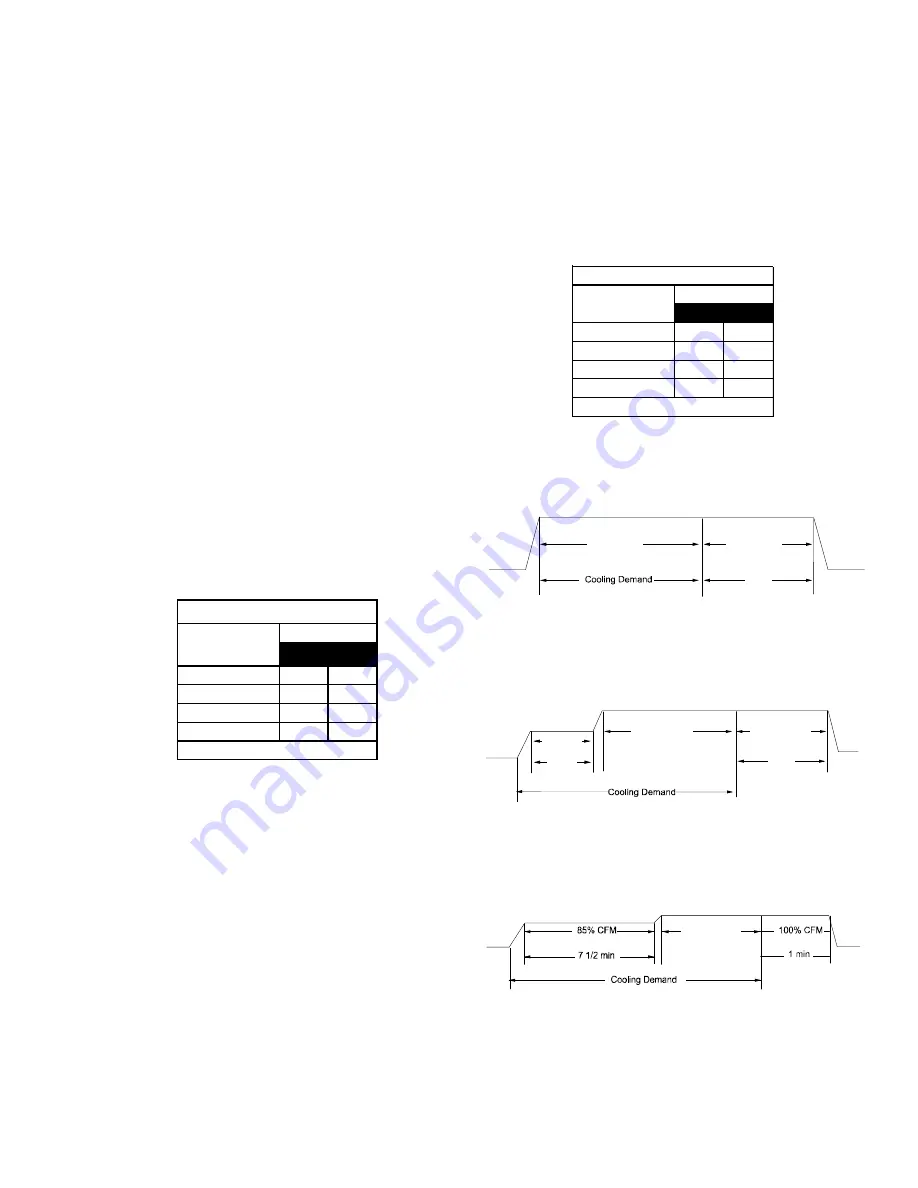

•

Profile A

provides only an OFF delay of one (1) minute

at 100% of the cooling demand airflow.

OFF

100% CFM

100% CFM

1 min

OFF

•

Profile B

ramps up to full cooling demand airflow by

first stepping up to 50% of the full demand for 30 sec-

onds. The motor then ramps to 100% of the required

airflow. A one (1) minute OFF delay at 100% of the

cooling airflow is provided.

50% CFM

1/2 min

100% CFM

100% CFM

1 min

OFF

OFF

•

Profile C

ramps up to 85% of the full cooling demand

airflow and operates there for approximately 7 1/2 min-

utes. The motor then steps up to the full demand air-

flow. Profile C also has a one (1) minute 100% OFF

delay.

100% CFM

OFF

OFF

4. Continuous fan speeds that provide 25, 50, 75 and 100%

of the furnace’s maximum airflow capability are select-

able via dip switches S5- 3, 4.

Example:

If the furnace’s maximum airflow capabil-

ity is 2000 CFM and 25% continuous fan

speed is selected, the continuous fan

speed will be 0.25 x 2000 CFM = 500 CFM.

5. Locate the blower speed selection DIP switches on

the integrated control module. Select the desired “cool-

ing” speed tap by positioning switches 1 and 2 appro-

priately. Select the desired “adjust” tap by positioning

switches 3 and 4 appropriately. To enable adjustments

and select -5, 5, -10 or 10% trim, you must set dipswitch

S5-2 to ON. If S5-2 is in the OFF position, you will

receive 0% trim. Refer to the following figure for switch

positions and their corresponding taps. Verify CFM by

noting the number displayed on the dual 7-segment

LED display.

6. The multi-speed circulator blower also offers several

custom ON/OFF ramping profiles. These profiles may

be used to enhance cooling performance and increase

comfort level. The ramping profiles are selected using

DIP switches S4- 1, 2. Refer to the following figure for

switch positions and their corresponding taps. Refer to

the bullet points below for a description of each ramp-

ing profile. Verify CFM by noting the number displayed

on the dual 7-segment LED display.

1

2

A*

OFF

OFF

B

ON

OFF

C

OFF

ON

D

ON

ON

Switch Bank: S4

DIP Switch No.

(*Indicates factory setting)

Ramping

Profiles

7. Select the heating speed for your model from the heat-

ing speed chart in the Specification Sheet. The adjust

setting (already established by the cooling speed se-

lection) determines which set of speeds are available.

The selected speed must provide a temperature rise

within the rise range listed with the particular model.

Example:

If the DM80VC604B* is set for 1210 CFM

on cooling, the “ADJUST” is set to “+”

(plus). The four heating speeds available

are “A Plus”, “B Plus”, “C Plus”, and “D

Plus”. “A Plus” has a rise of 38

°

F for both

stages which is within the 20-50°F rise

range for the DM80VC604B*. This set-

ting will keep electrical consumption to a

minimum. Set the “Heat” speed DIP

switches to “A”.