4 Installation

Installation manual

11

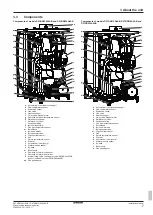

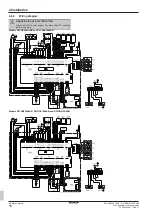

D2CND024A1/4AB + D2TND012~024A4AB

Wall-mounted condensing boiler

3P469346-3N – 2019.11

4.4

To mount the unit

1

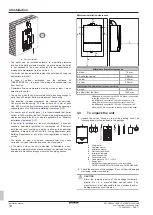

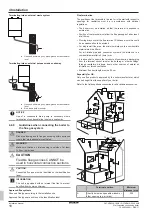

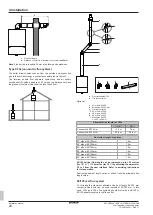

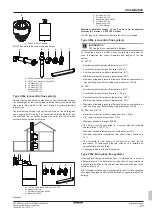

The mounting template shows the position for the horizontal

flue. If there is no hole in the wall for the flue piping, drill one. If

there is already a hole in the wall for the flue piping, you can

use this hole as a starting point to determine the position of the

mounting bracket, according to the template. Flue duct must

incline 3° away from the unit, to allow the condensate to drain

back to the boiler.

>3°

200

127

200

DN100

>3°

2

Drill holes for the mounting bracket (Ø10 mm). Fasten the

mounting bracket to the wall according to mounting template.

d=10 mm

3

Hang the unit on the bracket. Make sure the unit is latched to

the bracket.

4.5

Central heating system

requirements

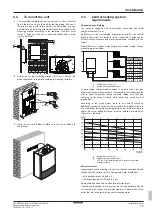

Expansion vessel sizing

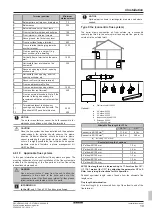

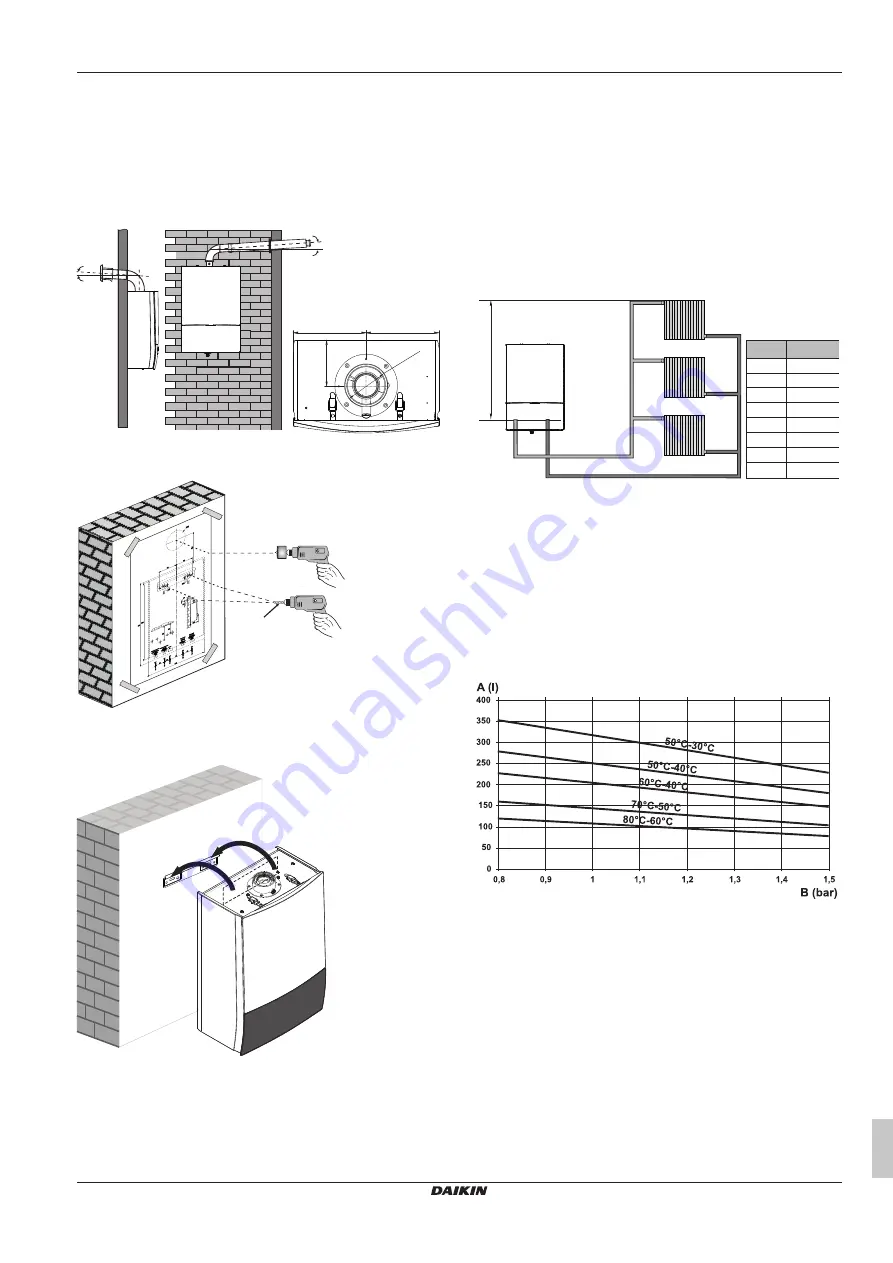

The boiler is equipped with an expansion vessel that has initial

charge pressure of 1 bar.

Sufficiency of the incorporated expansion vessel for the central

heating circuit that the boiler is to be connected to depends on

system charge pressure and water temperature circulating in the

circuit.

Determination of system water height and related system charge

pressure are given below:

h

p

≤6 m

0.8 bar

7 m

0.9 bar

8 m

1.0 bar

9 m

1.1 bar

10 m 1.2 bar

11 m

1.3 bar

12 m 1.4 bar

13 m 1.5 bar

h

h

System water height (m)

p

System charge pressure (bar)

In case system charge pressure needs to be more than 1 bar, gas

side initial charge pressure must be increased to the pressure value

that is equal to system charge pressure. Make sure that gas

charging to the vessel is done while boiler and circuit are not

pressurized.

According to the graph below, there is no need to install an

additional expansion vessel for the systems with a water volume in

the area below the operating temperature curve. If water volume is

above the curve, additional vessel must be installed, preferably on

the return to the boiler.

A

System water volume (l)

B

System charge pressure (bar)

*

50°C-40°C temperature regime is given for underfloor

heating systems

Water treatment

Inappropriate central heating circuit water reduces functionality and

efficiency of the boiler over time. Appropriate water should have:

▪ pH degree between 6.5 and 8.5

▪ Hardness less than 15°fH and 8.4°dH

Appropriate additives can be used for water treatment.

If antifreeze is needed for the system, the chosen antifreeze should

not interact with rubber, commercial plastic and metal parts of the

boiler that are in contact with the central heating water.

Содержание D2CND024A4AB

Страница 31: ......