IOM 1206-1

7

Installation and Application Information

Water Flow Limitations

Constant Evaporator Flow

The evaporator flow rates and pressure drops shown on

page 18

are for full load design purposes. The maximum flow

rate and pressure drop are based on a 6°F temperature drop.

Avoid higher flow rates with lower temperature drops to

prevent potential control problems resulting from a very small

control band and limited start up/shut off temperature changes.

The minimum flow and pressure drop is based on a full load

evaporator temperature drop of 16°F. Evaporator flow rates

below the minimum values can result in laminar flow causing

freeze-up problems, scaling and poor control. Flow rates above

the maximum values will result in unacceptable pressure drops

and can cause excessive erosion, potentially leading to failure.

Variable Evaporator Flow

Reducing evaporator flow in proportion to load can reduce

system power consumption. The rate of flow change should be

a maximum of 10 percent of the flow per minute. For example,

if the maximum design flow is 200 gpm and it will be reduced

to a flow of 140 gpm, the change in flow is 60 gpm. Ten

percent of 200 gpm equals 20 gpm change per minute or a

minimum of three minutes to go from maximum to minimum.

Do not reduce flow lower than the minimum flows listed in the

evaporator pressure drop section,

page 18

. The water flow

through the evaporator must remain between the minimum and

maximum values listed. If flow drops below the minimum

allowable, large reductions in heat transfer can occur. If the

flow exceeds the maximum rate, excessive pressure drop and

tube erosion can occur.

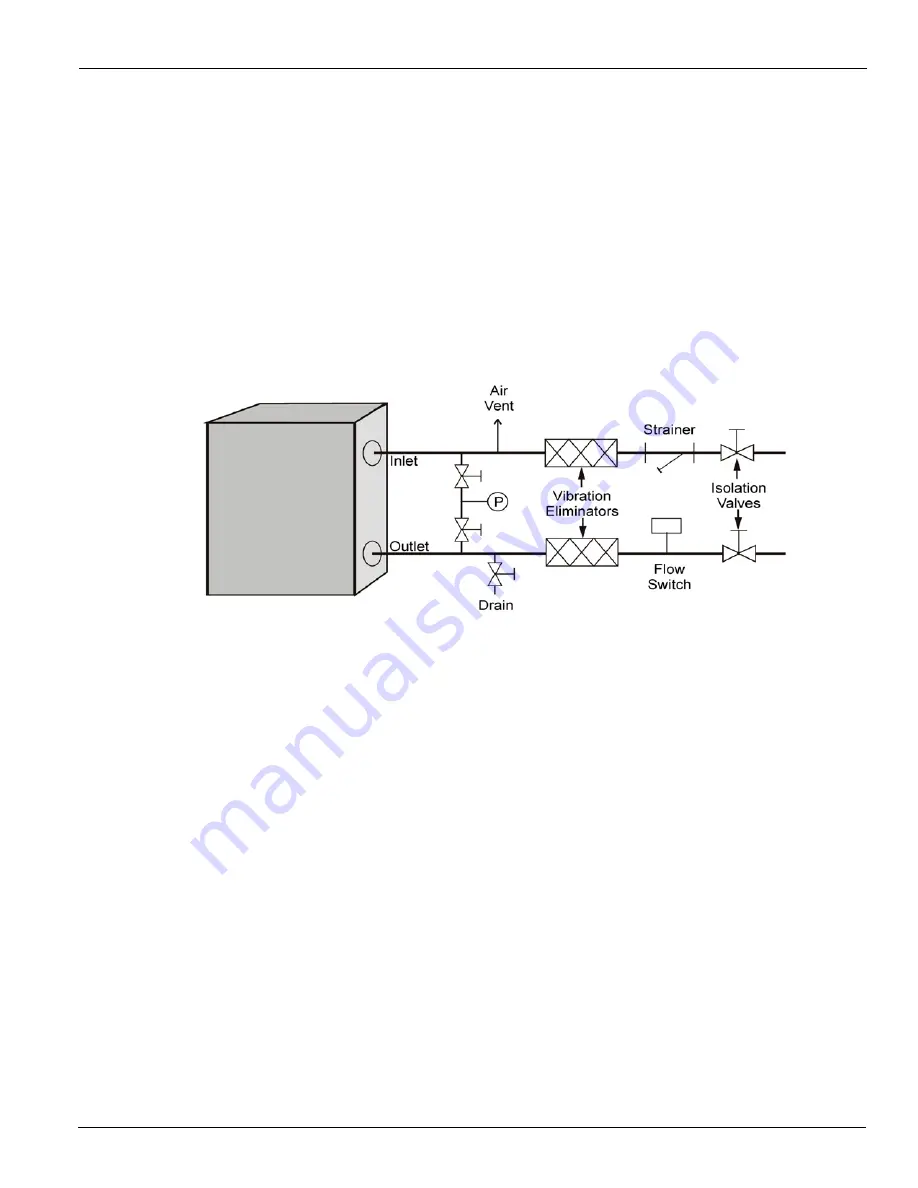

Figure 7: Typical Piping, Brazed-Plate Evaporator (models AGZ030E-070E)

Install piping with minimum bends and changes in elevation to

minimize pressure drop. The following issues should be

considered when designing and installing water piping:

1

Vibration eliminators to reduce vibration and noise

transmission to the building.

2

Shutoff valves are required to isolate the unit from the

piping during unit servicing.

3

Manual or automatic air vent valves at the high points of

the system. Drains must be installed at the lowest points

in the system.

4

Adequate water pressure must be maintained (expansion

tank or regulating valve).

5

Temperature and pressure indicators located at the unit

are required to aid in unit servicing.

6

Chilled water piping and strainer must be supported

independently from the unit.

7

Flush the system water piping thoroughly before making

connections to the unit evaporator. Design the water

piping so the chilled water circulating pump discharges

into the evaporator inlet.

8

The unit's evaporator has a thermostat and heater to

prevent freeze-up down to -20 F ( 29 C). The heating

cable can be wired to a separate 115 V supply circuit. As

shipped from the factory, the heating cable is wired to the

control circuit. All water piping to the unit must also be

protected to prevent freezing.

9

If the unit is used as a replacement chiller, flush the

system thoroughly before unit installation. Regular water

analysis and chemical water treatment for the evaporator

loop is recommended immediately at equipment start-up.

10

The total water volume in the system should be sufficient

to prevent frequent "on-off" cycling. Turnover rate

should not be less than 4 minutes for normal variable

cooling loads.

11

When glycol is added to the water system for freeze

protection, the refrigerant suction pressure will be lower,

cooling performance less, and water side pressure drop

greater. If the percentage of glycol is high, or if

propylene is used instead of ethylene glycol, the added

pressure drop and loss of performance could be

substantial. When Glycol or Ice are selected as Unit

Mode, the MicroTech III control will automatically reset

the available range for the Leaving Water Temperature,

Freezestat and Evaporator Pressure settings.

12

Reset the freezestat setting to 6 degrees F (3.3 degrees C)

below the leaving chilled water setpoint temperature

after the glycol percentage is verified safe for the

application. See the section titled "Glycol Solutions" on

page 9

for additional information concerning glycol.