– 5 –

4.

Changing Tungsten Electrode

(From

φ

3.2 to

φ

1.6)

4.1 Parts Necessary for

φ

1.6

●

Tungsten electrode (

φ

1.6 – 150 mm)

●

Collet body (for

φ

1.6) One set each

●

Collet (for

φ

1.6)

●

Lea collet (for

φ

1.6)

4.2 How to Change

●

Remove a set screw and take out a lea collet.

●

Loosen a lea collet body by turning its head and remove a nozzle, a collet body, a tungsten electrode

and a collet.

●

Insert a tungsten electrode (

φ

1.6) into a collet (for

φ

1.6) prepared, and then screw that into a collet

body (for

φ

1.6).

DO NOT forget to change an insulator as well when changing a collet body from

φ

3.2 to

φ

1.6.

●

Screw a nozzle into a collet body.

●

Insert a lea collet (for

φ

1.6) into a lea collet body.

●

Adjust the length of the part of a tungsten electrode that is sticking out according to the shape of the

welded and the location to be welded.

●

As soon as the length to be stuck out is decided, tighten the head of a lea collet body and mount a set

screw.

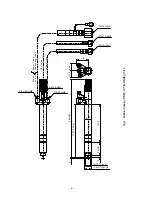

Fig. 2

CAUTION

●

Make sure to tighten a collet body and a torch body firmly. If

either of them is loose even slightly, a collet might be burned and

seized up or an operator might get burn due to the heat-up.

CAUTION

●

Stick out an electrode 5 to 10 mm from the tip of a nozzle. If the

tip of the electrode is located inside the nozzle, the nozzle might

become damaged due to the arc heat-up.

5.

Connection to Welding Power Source

CAUTION

●

Tighten each connection firmly. If there is any loosened part, fire or

burn might be caused due to the heat-up.

●

Refer to an instruction manual for each welding power source, and connect a torch properly.

Thoriated Tungsten Electrode

Collet Body

Insulator

Set Screw

Lea Collet

Lea Collet Body

Torch Body

Collet

Nozzle