−

S6

−

3.

Handling Precautions

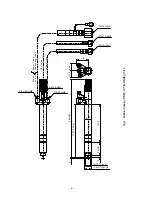

3.1 Coolant

CAUTION

●

Be sure to keep the flow of coolant at more than 1 liter per minute.

(Water pressure of more than 0.1 to 0.3 MPa is required at a torch

inlet). Insufficient flow of coolant may damage a welding torch.

●

NEVER apply air-cooling.

●

NEVER use a welding torch that had a water leak because doing so might cause an electric

shock.

3.2 Cable Hose

CAUTION

●

Never let cable hoses touch any heated part of the welded, put

something heavy on top nor bend them excessively because the

welding torch might become damaged.

3.3 Replacement of Parts

CAUTION

●

To prevent burns, observe the following.

●

Do not directly touch the high-temperature parts of a nozzle, an electrode and so on.

●

When welding, wear suitable protection such as leather gloves for welding.

●

Do not replace torch tip elements before they cool off.

CAUTION

●

If any parts are damaged, replace them with new ones for further

safety and better quality.

●

Be sure to place an order for replacement at our sales office or our agency.

CAUTION

●

Wear protective glasses for eye protection when grinding an electrode.

●

Follow safety instructions of a grinder or an electrode grinder when grinding an electrode.

HANDLING PRECAUTIONS