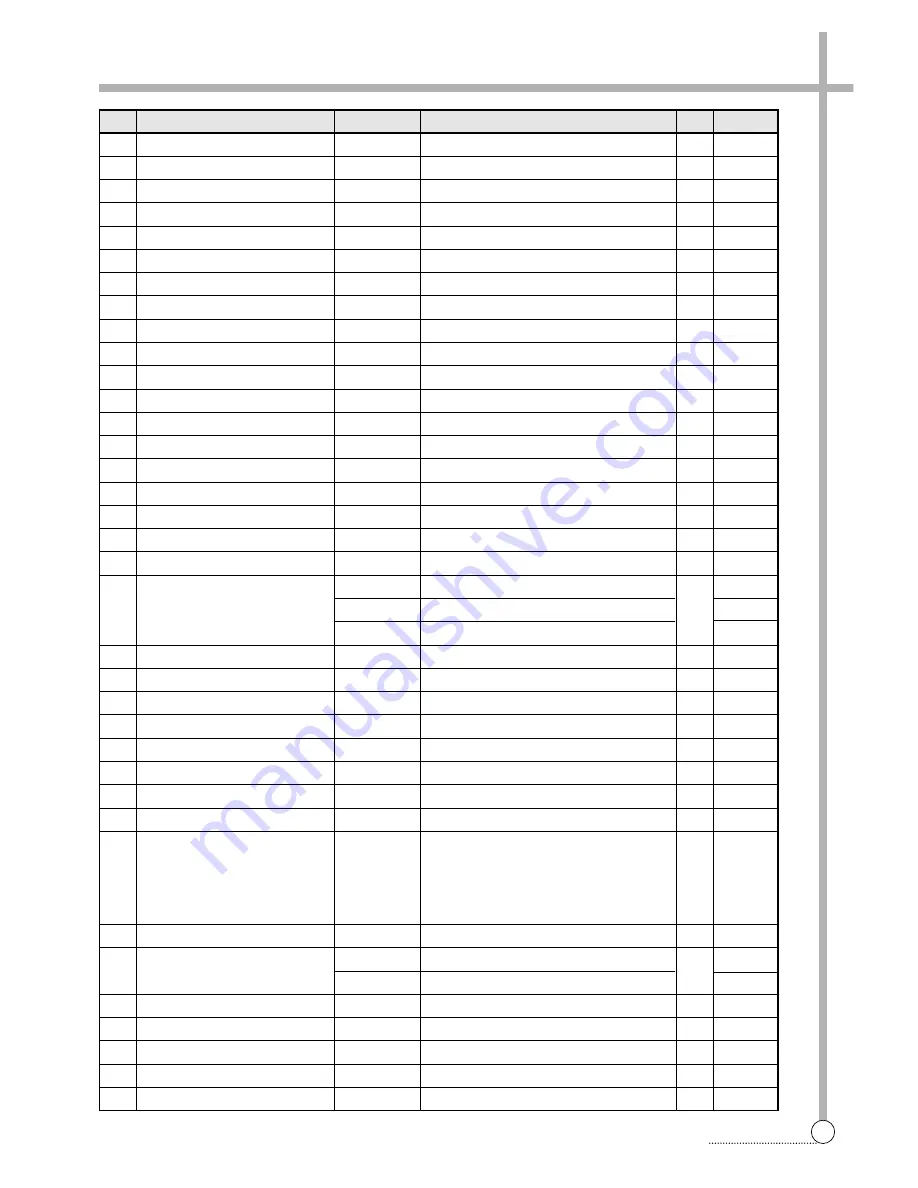

17

EXPLODE VIEW AND PARTS LIST

No.

PART NAME

PART CODE

SPECIFICATION

Q'TY REMARK

D01

TUB REAR AS

3618829900

TUB REAR(FRPP) + BEARING HOUSING(ALDC)

1

D02

BEARING INNER

3616304700

6205ZZ SHENS

1

D03

BEARING OUTER

3616304800

6204ZZ SHENS

1

D04

WATER SEAL

361A600300

NBR

1

D05

GASKET TUB

3612324100

PI=4.5, L=1650, EPDM

1

D06

FIXTURE HEATER

3612009400

SUS, PI=2

1

D07

TUB FRONT

3618829600

FRPP

1

D08

GASKET

3612323500

EPDM

1

D09

CLAMP GASKET AS

3611204520

HSW3

1

D10

DRUM SUB AS

3617010400

SUS T=0.4

1

D11

SPIDER AS

361A301000

SPIDER(ALDC-8) + SHAFT(SM45C)

1

D12

SPECIAL BOLT

3616063000

STS430 M6*21 SI-LOCK

3

D13

LIFTER WASH

361A401110

NANO

3

D14

SPECIAL SCREW(TUB)

3616062700

SWRCH18A 5.6*30

12

D15

PULLEY

3618433210

PA6+GF30%, SERRATION

1

D16

SPECIAL BOLT AS(PULLEY)

3616063100

SWRCH10A M8*22 PW SI-LOCK

1

D17

UNIT MOTOR UNIVERSAL

36189L5H00

SOYEA 2POLES 38T

1

D18

SPECIAL SCREW(MOTOR)

3616062800

SWRCH18A 7.4*25.5

2

D19

BELT V

3616591300

GATES 3PJ1134 BUTADIENE RUBBER

1

3612802450

220V 1.8KW IRCA

D20

HEATER WASH

3612802460

230V 1.8KW IRCA

1

3612802470

240V 1.8KW IRCA

D21

THERMISTOR WASH

361AAAAB10

R25=1.704K

Ω

, R80=11.981K

Ω

1

D22

HARNESS EARTH

3612794450

L=180

1

D23

BALANCER WEIGHT

3616108900

PP, INSERT 4KG

2

D24

SPECIAL SCREW(BALANCER)

3616062900

SWRCH18A 8*31 PW

6

D25

HOSE INLET

3613271600

EPDM

1

D26

CLAMP HOSE I

3611201400

HSW3, D=2.6, MFZN D=38

1

D27

SPRING SUSPENSION

3615115900

K=0.39, L=137

2

D28

FRAME TOP

3612208500

SGCC T=1.2

HOSE DRAIN(EPDM) + AIR TRAP(PP)

D29

HOSE DRAIN AS

3613272300

+ HOSE AIR(ID=4.0, OD=8, L=560, EPDM)

1

+ CLAMP AS(ID=81, CIMA)

+ CLAMP HOSE(D=26) + CLAMP HOSE I(D=38)

D30

SCREW TAPPING

7122401411

T2S TRS 4X14 MFZN

1

D31

DAMPER FRICTION

361A700110

70N AKS

2

361A700140

70N CIMA

D32

DAMPER PIN

361A700200

AKS D=14.5

2

D33

UNIT BUBBLE PUMP AS

36189L4140

220-240V RP CHUSHION=760

1

D34

SPECIAL SCREW(BUBBLE)

3616007400

T2S TRS 4X10+24

2

D35

EMI FILTER(K27)

3611908740

0.22UF

1

D36

SCREW TAPPING

7122401411

T2S TRS 4X14 MFZN

1

Содержание DWD-M8011

Страница 17: ...16 EXPLODE VIEW AND PARTS LIST TUB AS ...

Страница 19: ...18 EXPLODE VIEW AND PARTS LIST CABINET AS ...

Страница 30: ...10 WIRING DIAGRAM 29 WIRING DIAGRAM ...