User Manual

–

VisiTouch Series

VisiTouch series

–

User Manual

A

PR

.

2020

V1.1

44/45

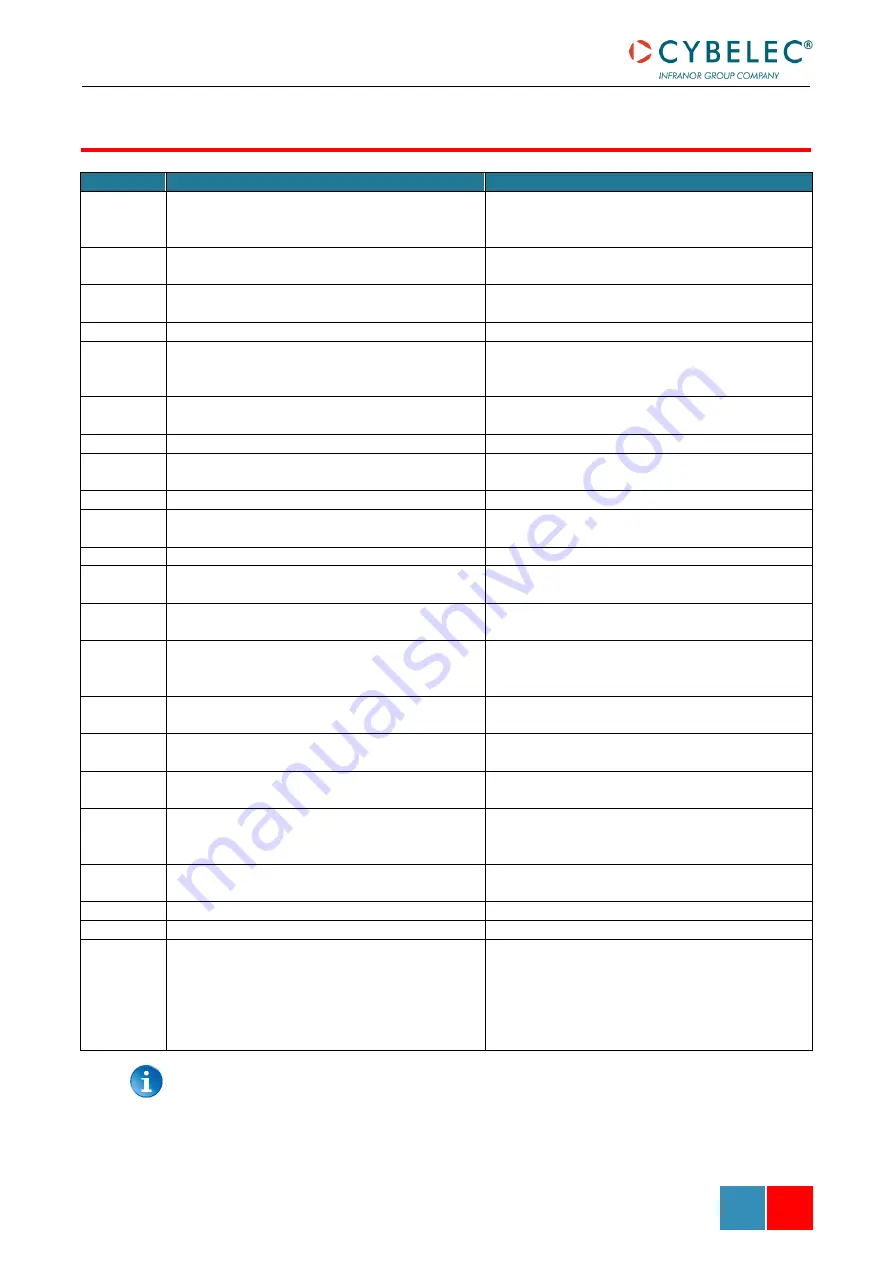

M

SG

N

R

.

D

ESCRIPTION

C

OMMENT

13

Command refused because pinch point is below

Y1 and Y2 bottom dead centre

Check the value of the PP correction, and the

value of the BDC correction in the User Preference

page.

14

Command refused because the speed

commutation point is below the pinch point

15

Command refused because low speed up speed

out of limits

16

Command refused because speed out of limits

17

Command refused because Bottom Dead Centre

Y1 and Y2 are too different

Difference between target values of Y1 and Y2

bigger than the limit value defined in the machine

parameter. Call you dealer.

18

Command refused because pinch point is outside

stroke limits

19

Command refused because beam is moving

20

Command refused because Bottom Dead Centre

is outside the beam limits

26

Command refused because beam is in emergency For example, beam out synchronism tolerance.

27

Command refused because Synchronism

controller parameters not in range

Problems with limit parameters (max and min) of

the beam. Contact your dealer.

28

Command refused because stop is active

37

Command refused because zero has not been

found yet

Beam is not indexed.

40

Command refused because bend data have never

been loaded

44

Command refused because beam is in

emergency. Only a manual down of the upper

axis is allowed

Only the axis with the highest position is allowed

to be moved manually down.

49

Command refused because beam is not at high

end of stroke position

52

Command refused because the beam is

requested to go to TDC

53

Command refused because a beam cycle is not

running

248

Synchronism limit reached, Y1: {0} Y2: {1}

Height difference between Y1 and Y2 bigger than

the limit value defined in the machine parameter.

Call you dealer.

265

Error with Oil Leakage Control. Cancelling

operation

267

Beam not indexed, no move

606

High speed down stopped by safety speed switch

607

Command refused because other command still

active

Order of priority is as follows :

1.

Stop Command

2.

Go to TDC MAX

3.

Go to next TDC

4.

Up command

5.

Down command

This table does not contain an exhaustive list of all the errors related to beam.

If the message number is not explained here, please write it down and contact

your dealer.

B

EAM

E

RROR

M

ESSAGES