19

I.B. 8926-1A

Part 8

INSPECTION PRIOR TO ENERGIZING

1. Before energizing the motor control center

(MCC), conduct a thorough inspection to make

certain that all foreign materials such as tools,

scraps of wire and other debris are removed

from all units and the structure. Remove any

accumulation of dust and dirt with a vacuum

cleaner.

2. All circuit connections are tightened at time of

assembly by power-driven tools with controlled

torque. However, the vibrations experienced in

transit may loosen some of these connections.

Check at least 10% of the total connections for a

tight connection.

Should this spot-check

reveal some loose connections, it will be

necessary to check all connection points.

The connections to be checked include bus

hardware, circuit breaker and switch terminals,

contactor and relay terminals and terminal

blocks. Always check the incoming line

connections. Tighten to the torque values shown

in Tables 8-1.

3. Remove all blocks or other temporary holding

means used for shipment from all component

devices in the MCC interior.

4. Check the enclosure to see that it has not been

damaged so as to reduce electrical spacings.

5. Compare all circuits for agreement with the

wiring diagrams which accompany the MCC. Be

sure that each motor is connected to its intended

starter.

6. Make certain that field wiring is clear of live

busses and physically secured to withstand the

effects of fault current.

7. Check to determine that all grounding

connections are made properly.

8. Check all devices for damage. Make all

necessary repairs or replacements, prior to

energizing.

9. Manually exercise all switches, circuit breakers,

and other operating mechanisms to make

certain that they are properly aligned and

operate freely.

10. Test any ground-fault protection systems that

were furnished.

11. Set any adjustable current and voltage trip

mechanisms to the proper values.

12. Ensure that overload relay heater elements are

installed and selected to the full-load current

shown on the nameplate of each motor.

13. Install power circuit fuses in the fusible switches

in accordance with NEC application

requirements. Make sure that fuses are

completely inserted in the clips provided. Do not

attempt to defeat the rejection feature on the

fuse clip, when provided.

14. Do not operate a current transformer with its

secondary circuit open. Insure current

transformer is connected to a load, or a

secondary shorting bar is installed.

15. To prevent possible damage to equipment or

injury to personnel, check to insure that all parts

and barriers that may have been removed

during wiring and installation have been properly

reinstalled.

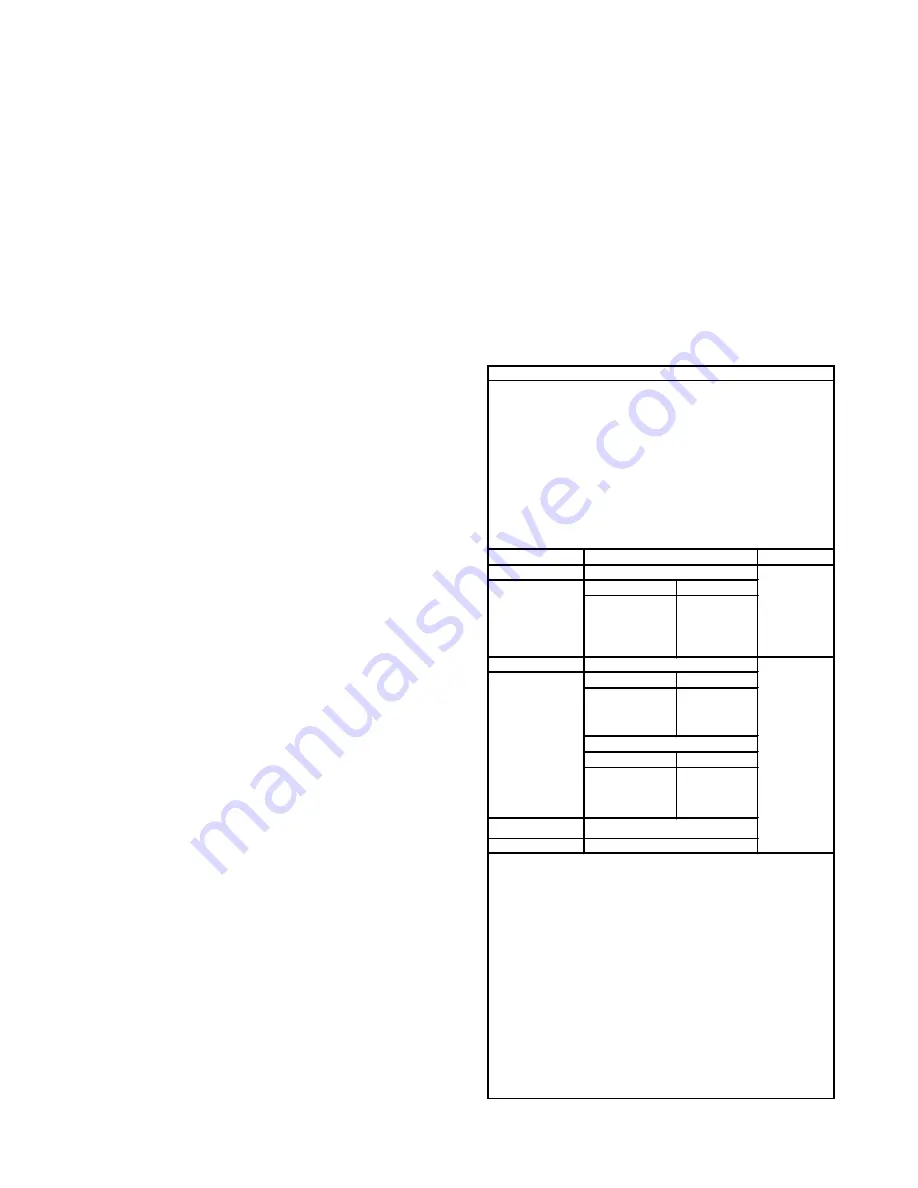

Coil Leads……………………………………………. …….8 lb.-in.

Relays……………………………………………………

…….8 lb.-in.

Push Buttons……………………………………….. …….8 lb.-in.

Control Fuse Blocks……………………………………

…….8 lb.-in.

Auxiliary Contacts………………………………………….8 lb.-in.

Control Wiring Terminal Blocks

Side Mounted Lug/Compression………………… …....9 lb.-in.

Rail Mounted Lug Type…………………………….…...12 lb.-in.

Rail Mounted Compression Type………………….

…...18 lb.-in.

Using Overload

Catalog Number

Conductors

C306DN3

Wire size (AWG) Torque (lb.-in.)

14-10

35

8

40

6 - 4

45

3 - 2

50

For Starters

Wire size (AWG) Torque (lb.-in.)

8

40

6 - 4

45

3 - 2

50

Socket Size (In.) Torque (lb.-in.)

3/16

120

1/4

200

5/16

250

Size N and Size 4

Size 5 and Size 6

30 Amp Fuse Assy………………………………… ……25 lb.-in.

60 Amp Fuse Assy………………………………… ……50 lb.-in.

100 Amp Fuse Assy………………………………………50 lb.-in.

200 Amp Fuse Assy………………………………. …..300 lb.-in.

400 Amp Fuse Assy………………………………. …..300 lb.-in.

600 Amp Fuse Assy………………………………. …..300 lb.-in.

#2/0-350 MCM…………………………………….. …..360 lb.-in.

#2/0-650 MCM…………………………………….. …..360 lb.-in.

#2/0-750 MCM…………………………………….. …..500 lb.-in.

500-1000 MCM…………………………………….. …..600 lb.-in.

All………………………………….. ………….275 lb.-in.(23lb.-ft.)

20 lb.-in.

BREAKERS-

Refer to Torque Values on Breaker Case

Incoming Line Lugs:

Bus Bolts:

Size 3

Socket Head Screw

275 lb.-in.

500 lb.-in.

Use 75

Degrees C

copper or

aluminum

conductors

Slotted Head Screw

Fused Switches:

TABLE 8-1 DRIVING TORQUE

Control Wiring:

Power Wiring: Starters

C306GN3 and

size 2 Contactor

Tightening Torque - Load Side

Use 75

Degrees C

copper

conductors

Содержание Freedom 2100 Series

Страница 31: ...31 I B 8926 1A Part 11 PLAN VIEWS...