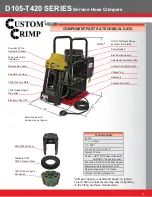

D105-T420 SERIES

Service Hose Crimpers

8

LUBRICATION PROCEDURE

Photo # 1

Photo # 2

Photo # 3

Grease Point # 1

Apply a thin layer of CrimpX oil (supplied with the

crimper), or a molybdenum disulfi de high pressure

grease on the surface of the cone base.

(as shown in photo # 1).

Grease Point # 2

Before sliding the standard pressure plate (or the notched

pressure plate) over the correct dies, apply a thin layer of

CrimpX oil (supplied with the crimper), or a molybdenum

disulfi de high pressure grease, on the entire area that the

dies come in contact with (as shown in photo # 2).

If Dies are sticking in the cone base:

Continue to lubricate

/ grease as explained above, in addition to lubricating each

die fi nger individually (as shown in photo # 3).

Note:

The die fi ngers must be lubricated at both positions

that come in contact with the pressure plate and the

cone base.

Note:

Lubrication is not required before each crimp.

Typical lubrication is after 100 crimps.

Notched Pressure Plate:

For use with 90 degree fi tting only.