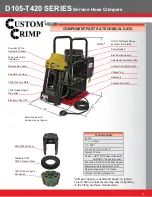

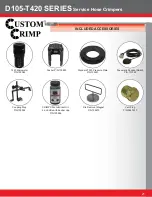

D105-T420 SERIES

Service Hose Crimpers

16

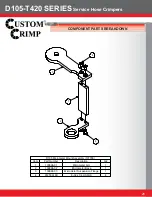

Step 11:

Check the fi nal crimp diameter with calipers to confi rm that

it is within manufacturer’s specifi cations.

Note:

Always consult with your hose and fi tting manufacturer to obtain

the must current crimp specifi cations.

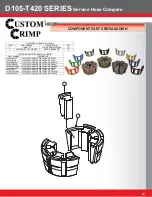

Step 9:

Set the

Micro-Crimp Adjuster

to the setting recommended by

the hose and fi tting manufacturer for the combination of hose and fi tting

being crimped.

NOTE: The T420 Micro-Crimp Adjuster is a direct reading

micrometer. Add the setting on the micrometer to the closed

diameter of the die set to obtain the fi nished crimp diameter.

For example: With a 23mm die set and the Micro-Crimp Adjuster set at

3.0, the fi nished crimp diameter would be 26.0 mm (23mm + 3.0mm).

Note:

Each die set has a limited range of diameters for which a satisfactory

crimp can be obtained. Always consult your hose and fi tting manufacturer

for the correct die set for the hose and fi tting being crimped.

Step 10:

Recheck the fi tting for the correct alignment in the die set and

depress the start/stop switch.

Depress and hold the Start/Stop switch, until the micrometer touched the

electronic red button as shown, “count one mississippi” the automatic

stop switch will shut the pump off, and the ram will return to the retracted

position. Allow the pusher to return to the retracted position as well.

CRIMPING WITH

NOTCHED

T420 PRESSURE PLATE