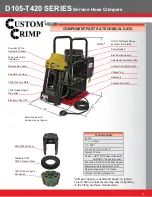

D105-T420 SERIES

Service Hose Crimpers

13

Note:

Follow the lubrication procedure prior to crimping procedure.

CAUTION:

Failure to lubricate the die set and pressure plate could

result in the die seizing in the cone base.

Step 1:

Make certain that the

Cone Base

is clean and lubricated prior

to inserting the die set.

Step 2:

Select the

Correct Die Set

for the combination of hose and

fi tting being crimped.

Note:

Consult your hose and fi tting manufacturer for the correct die size

for the combination of hose and fi tting being crimped.

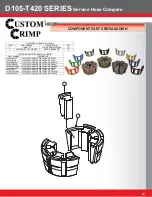

Note:

The number etched on the OD of the die ring represents the fully

closed diameter of the die set in millimeters. In addition, die sets are

rubber caged color-coded for easier identifi cation.

Step 3:

Lubricate the contact surfaces

, both the top and the outside

edges of the die fi ngers, with CrimpX oil (supplied with the crimper), or

a molybdenum disulfi de high pressure grease.

Failure to lubricate the contact surfaces with the correct lubricant

will cause the dies to seize in the cone base, causing damage

to the die set as well as possibly damaging the crimper.

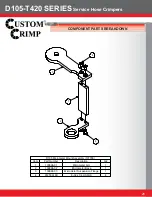

CRIMPING WITH

NOTCHED

T420 PRESSURE PLATE

WHEN USING THE NOTCHED T420 PRESSURE PLATE,

FOR USE WITH 90 DEGREE FITTING ONLY,

FOLLOW THESE PROCEDURES: