20

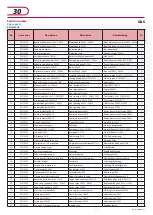

Gas - IT/UK/DE 08-12

20

230V

400V

ON

OFF

Attivazione alimentazione

Power supply activation

Aktivierung Speisung

Veri

fi

ca del funzionamento

Mettere in funzione il forno seguendo le istru-

zioni di seguito riportate.

Veri

fi

care il corretto funzionamento di tutti

i componenti elettrici, spiegando all’utente

come utilizzare in maniera ottimale l’appa-

recchiatura e come e

ff

ettuare le operazioni di

ordinaria manutenzione e di pulizia.

Operation Veri

fi

cation

Start up the oven using the instructions pro-

vided below.

$IFDL UIF DPSSFDU PQFSBUJPO PG BMM FMFDUSJDBM

DPNQPOFOUT XIJMTU FYQMBJOJOH IPX UP CFTU

use the appliance and how to carry out rou-

tine maintenance and cleaning operations to

the user.

Funktionsprüfung

Setzen Sie den Ofen wie folgt beschrieben in

Betrieb.

Prüfen Sie die korrekte Funktion aller elektri-

schen Komponenten und erklären Sie dem

Nutzer, wie der Apparat optimal genutzt wird

und wie die ordentlichen Wartungs- und Rei-

nigungsarbeiten durchzuführen sind.

Precollaudo

Prima della consegna al cliente, il forno viene

DPMMBVEBUPQSFTTPMFPóDJOFEJDPTUSV[JPOFTJB

sotto il pro

fi

lo della funzionalità che della si-

curezza.

Presso l’utilizzatore

fi

nale, all’atto del primo

ciclo di avviamento, si raccomanda di innalza-

SFMBUFNQFSBUVSBöOPBEVOWBMPSFEJ¡$

mantenendolo per almeno 8 ore.

In questa fase il forno produrrà fumi e odori

sgradevoli dovuti all’evaporazione dell’umidi-

tà contenuta nei materiali isolanti.

Tali fumi e odori scompariranno nei successivi

cicli di funzionamento.

É da far notare che modi

fi

che all’ambiente di

installazione, che possono in

fl

uenzare l’ap-

porto di aria comburente, rendono neces-

sario un nuovo controllo del funzionamento

dell’apparecchio.

ATTENZIONE:

Per l’accensione e la programmazione, fare

riferimento al capitolo d’uso utente.

Pre-test

Prior to delivery to the customer, the oven is

tested at the manufacturer’s workshops both

with regard to functionality as well as to safety.

When the unit is turned on for the

fi

rst time is

recommended that the temperature is set at

¡$BOEMFGUPOGPSBUMFBTUIPVST

During this phase, the oven will produce

fumes and unpleasant odours due to the

evaporation of the moisture contained in the

insulation.

These fumes and odours will disappear dur-

ing the subsequent operating cycles.

It should be pointed out that changes to the

place where it is installed may in

fl

uence the

fl

ow of combustion air, making it necessary to

check appliance operation again.

ATTENTION:

Please refer to the user’s manual for start-

up and programming.

Vorabnahme

Vor der Auslieferung an den Kunden wird der

Ofen in den Konstruktionswerkstätten geprüft,

sowohl bezüglich der Funktionen als auch der

Sicherheit.

Beim ersten Einschaltzyklus beim Endnutzer

muss die Temperatur bis zu einem Wert von

¡$FSIÚIUVOEEBOOGàSNJOEFTUFOT4UVO

-

den gehalten werden.

In dieser Phase entstehen im Ofen Dämpfe und

schlechte Gerüche, die durch die Feuchtigkeit

entstehen, die im Isoliermaterial enthalten ist.

Diese Dämpfe und Gerüche verschwinden in

den nachfolgenden Betriebszyklen.

Es muß darauf hingewiesen werden, daß eine

Veränderung der Installationsumgebung, die

zur Beein

fl

ussung der Zufuhr sauersto

ff

halti-

ger Luft führen kann, eine erneute Funtions-

kontrolle des Gerätes nötig macht.

ACHTUNG:

Für das Einschalten und die Programmie-

rung auf das Kapitel Benutzerbetrieb Be-

zug nehmen.

Содержание Gas G12 - 33

Страница 2: ......

Страница 34: ...34 Gas IT UK DE 08 12 note notes Anmerkungen ...

Страница 35: ...Gas IT UK DE 08 12 35 ...