12/2008 - Art. Nr. 4200 1013 9300A

33

Commissioning

Commissioning the burner also involves

simultaneous installation by the fitter or

his representative; only they can

guarantee the boiler room complies with

currently accepted practices and

regulations in force.

Beforehand, the fitter must have

completely filled the suction line with fuel

oil, vented the primary filter and checked

that the manual quarter-turn and

protection valves function correctly.

Preliminary checks

• Check the available electric voltage

and compare it with the recommended

value.

• Switch off the burner power supply.

• Check absence of voltage.

• Close the fuel valve.

• Read the manufacturer's service

instructions for the boiler and the

regulator.

• Check the following:

- the water pressure in the heating

circuit,

- the operation of the circulator,

- the opening of the mixer valve,

- the setting of the boiler thermostat

and the ambient thermostat,

- the rating of the fuses,

- that the combustion air supply to the

boiler house and the combustion

product exhaust pipe are working

correctly and compatible with burner

capacity and fuel,

- the operation of the draught

regulator on the flues,

- the fuel oil level in the tank,

- that the aspiration line has been

filled,

- the position of the hoses:

- suction and return,

- the supply pressure of the fuel, if

boost: 2 bar max,

- the opening of the protection and

primary filter valves.

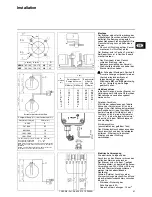

Setting

The burner is preset in the factory.

If this pre-setting does not correspond to

the boiler power, follow the instructions

below.

• In the table opposite, choose the

nozzle calculated for the nominal

power of the boiler with an efficiency

rating of 92%.

• Carry out the following settings on the

combustion head:

- dimension

Y

graduated from 0 to

20 mm,

- manual control of the air flap

103B

graduated from 0 to 18.

Firing

• Close the regulator circuit.

• Unlock the control unit.

• The burner is in service.

• Wait until the reheater thermostat has

closed (for burners with reheaters).

The burner starts up

• Carry out a combustion check: CO

2

,

opacity and exhaust gas temperature.

To increase the CO

2:

• Reduce the air flap opening and vice

versa. Modifying its value may require

a correction of dimension

Y

, by turning

screw

3

.

To modify the exhaust gas index

• Open the air flap to make it lighter, and

vice versa.

• Check the combustion parameters

under actual operating conditions

(doors closed, etc.), and test that the

various circuits are sealed.

• Record the results in the relevant

documents.

Safety checks

• Check, while the burner is functioning:

- the opening of the regulator circuit,

- the safety shutdown with lockout,

with no flame,

- the seal on the boiler front,

- the operation of the control devices

(if present),

- the vacuum pressure of the fuel

supply circuit, maximum 400 mbar

or 305 mm Hg.

1

Suction.

2

Return.

3

Nozzle outlet.

4

Pressure tap

G1/8

5

Vacuum gauge connector

G1/8

6

Pressure setting.

7

Single line indication.

10

Solenoid valve coil.

Y1

Solenoid valve.

Check for fuel oil leaks

• Connect a pressure gauge and a

vacuum gauge to the pump.

• The readings are taken while the

burner is operating.

• Check subsequently for leaks.

45°

60°

20

1,8

-

0,50

11

5

9

24

2,2

-

0,60

11

5

10

27,3

2,5

-

0,60

11

10

10

32,7

3,0

0,75

-

11

10

13

37,1

3,4

0,85

-

11

10

15

43,6

4,0

1,00

-

11

12

15

48

4,4

1,10

-

11

20

18

54

4,9

1,25

-

11

5

8

67

6,1

1,50

-

11

10

11

74

6,8

1,75

-

11

15

13

Air flap

103B

Scale values

Boiler power

kW

Fuel-oil flow

kg/h

Pump

pressure

bar

Nozzle Danfoss S

US Gal/h

Spray angle

Dimension

Y

mm

NC9 H101A

NC4 R101A

NC4 H101A

Burner

NC6 H/R101A

Содержание NC4

Страница 52: ...12 2008 Art Nr 4200 1013 9300A 52 R 1 2 9 BP1 BP1 B 2 BP2 R A4...

Страница 53: ...12 2008 Art Nr 4200 1013 9300A 53 230 1 14 2 15 3 16 4 17 L1 5 18 6 19 7 20 8 21 9 22 10 23 11 24 12 25 13 26...

Страница 54: ...12 2008 Art Nr 4200 1013 9300A 54 K 0 A B...

Страница 55: ...12 2008 Art Nr 4200 1013 9300A 55 BP1 c 400...

Страница 57: ...12 2008 Art Nr 4200 1013 9300A 57...

Страница 58: ...12 2008 Art Nr 4200 1013 9300A 58...

Страница 59: ...12 2008 Art Nr 4200 1013 9300A 59...