12/2008 - Art. Nr. 4200 1013 9300A

32

Installation

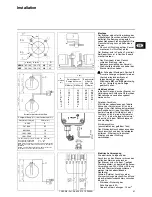

Assembly

The burner is secured on the boiler with

the flange supplied. Holes are drilled as

shown in the drawing. The flange gasket

can be used as a template.

• Mount the flange and its gasket on the

boiler. Check for leaks.

The burner is installed in position

1

.

If necessary, it may be installed in

position

2

or

3

.

• Insert the connecting nozzle into the

flange (insertion: see boiler manual).

• Tighten the clamp, raising the burner

slightly.

To fit it in position

2

, reverse the

display. To do this while the burner is

operating:

Hold buttons

BP1

and

BP2

down at

the same time, until you notice a

change.

Fuel oil connection

When connecting R 3/8 hoses to the

piping, allow for the burner to be

removed.

Two-line connection

The illustration opposite allows the

diameter (Ø) and the length (L) of the

piping to be determined from the suction

height (H+) or load (H-) (for fuel oil with

a density of 0.84, to a temperature of

10°C, in an installation which includes

one valve, one non-return valve and four

elbows, at the most).

Single line connection

(for a charged tank only)

Remove the return hose, remove the

connection and the bypass cap. Plug it

using a cylindrical cap and a seal.

Electrical connection

The electrical setup and the burner

connection must be performed in

compliance with the standards in force.

The burner is supplied with a 7 pin male

connector, to which the single-phase

230V-50Hz power supply with earth and

the thermostat are connected (diagram

opposite).

NB: External connection of an alarm

between S3 and N and an hour meter

between B4 and N.

- Rating of the protective fuse: 6.3A

- Conductor section: 1.5 mm

2

Corrected

H

(m)

L (m)

two-line pump 60 l/h

max

single line

US gal/h

0.60 1.00

Ø 4/6 mm

Ø 6/8 mm Ø 8/10 mm

4

3

2

1

0.5

0

-0.5

-1

-2

-3

17

14

12

10

9

8

7

6

4

-

54

47

40

34

31

27

24

21

14

8

80

70

60

51

46

42

-

-

-

-

48

42

36

30

28

25

-

-

-

-

Correction of altitude

Pump in suction (H +) or charging (H -) mode

Altitude (m)

Theoretical H (m)

0-500

0

501-800

0.5

801-1300

1.0

1301-1800

1.5

1801-2200

2.0

e.g.: altitude 1100m. Theoretical H = 1m actual H 2m.

Corrected H for suction 2 + 1 = 3m

Corrected H for charging 2 - 1 = 1m

Choose the Ø of the piping from the table, based on the

length expanded between the tank and pump.

If corrected H for suction exceeds 4m; make provisions for

a transfer pump (max. pressure 2 bar).

a (mm)

b (mm)

c

d

NC4/6

85-104 150-170

M8

45°

NC9

95-104 150-170

M8

45°

Содержание NC4

Страница 52: ...12 2008 Art Nr 4200 1013 9300A 52 R 1 2 9 BP1 BP1 B 2 BP2 R A4...

Страница 53: ...12 2008 Art Nr 4200 1013 9300A 53 230 1 14 2 15 3 16 4 17 L1 5 18 6 19 7 20 8 21 9 22 10 23 11 24 12 25 13 26...

Страница 54: ...12 2008 Art Nr 4200 1013 9300A 54 K 0 A B...

Страница 55: ...12 2008 Art Nr 4200 1013 9300A 55 BP1 c 400...

Страница 57: ...12 2008 Art Nr 4200 1013 9300A 57...

Страница 58: ...12 2008 Art Nr 4200 1013 9300A 58...

Страница 59: ...12 2008 Art Nr 4200 1013 9300A 59...