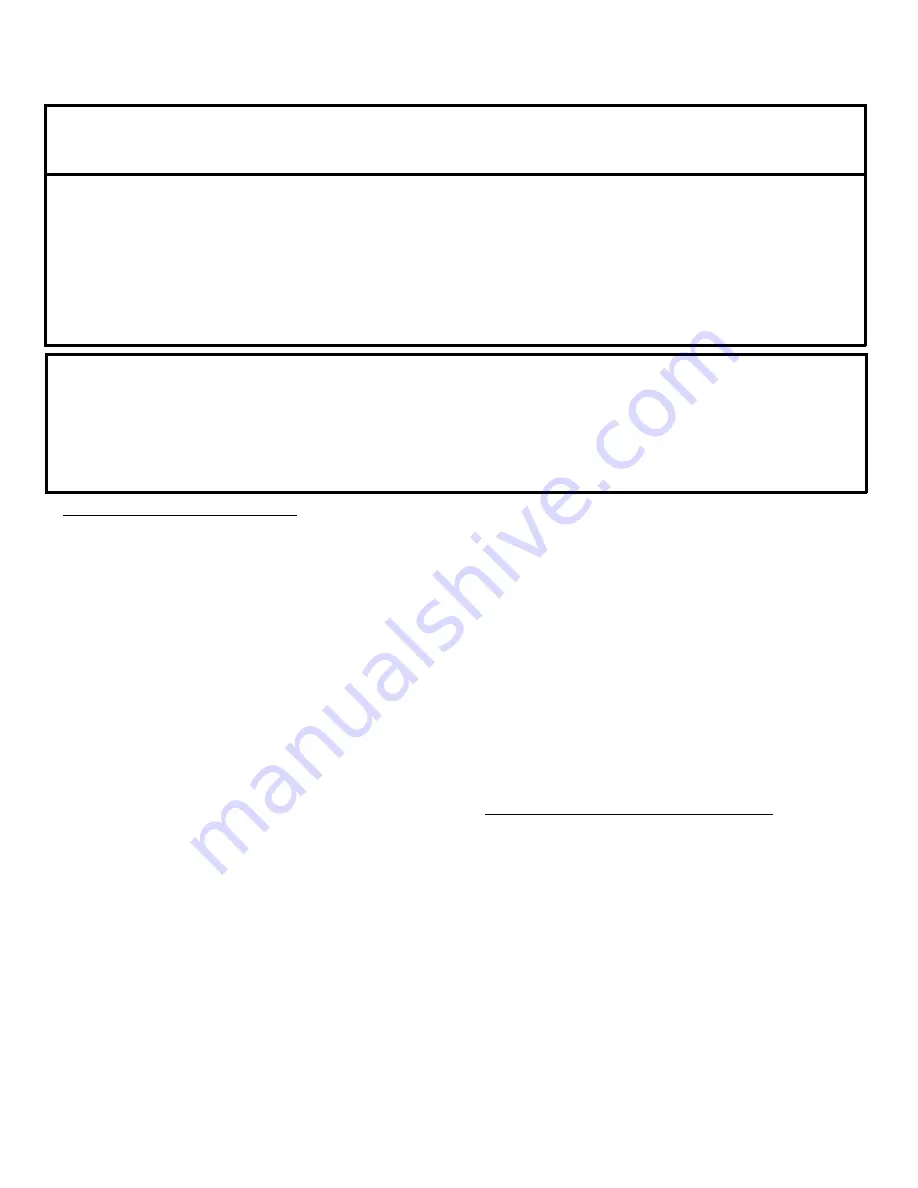

MODEL

HP

VOLT

PH

RPM

NEMA

FULL LOCKED

CORD

CORD

CORD

EMERSON

G.E.

NO.

(Nom) CODE

LOAD

ROTOR

SIZE

TYPE

OD

WINDING

WINDING

AMPS

AMPS

RESISTANCE

RESISTANCE

MAIN/START

MAIN/START

STEP512L

0.5

115

1

3450

F

12.0

55.0

14/3

SJTOW-A

0.390

1.70--16.6

STEP522L

0.5

230

1

3450

F

6.0

11.5

14/3

SJTOW-A

0.390

9.32--10.14

STEP532L

0.5

230

3

3450

G

3.4

7.8

14/4

SO

0.600

8.58--

STEP542L

0.5

460

3

3450

G

1.7

3.9

14/4

SO

0.600

34.32--

STEP552L

0.5

575

3

3450

G

1.4

3.1

14/4

SO

0.600

53.62--

STEP1022L

1.0

230

1

3450

B

8.0

13.8

14/3

SJTOW-A

0.390

2.83--15.14

STEP1032L

1.0

230

3

3450

K

5.4

21.3

14/4

SO

0.600

4.34--

STEP1042L

1.0

460

3

3450

K

2.8

10.7

14/4

SO

0.600

17.36--

STEP1052L

1.0

575

3

3450

K

2.3

8.6

14/4

SO

0.600

27.12--

Winding Resistance

±

5%, Pump rated for operation at

±

10% voltage at motor.

Standard Units:

(Optional - Moisture sensor & Power cable for 1 phase is 14/5 SO, 0.670 O.D,

replaces

standard SJTOW-A cable.)

(Optional - Temperature sensor cable for 3 phase models is 14/2 SOW, .530 O.D.)

(Optional - Moisture & Temperature sensor cable for 3 phase models is 18/5 SOW, 0.476 OD.)

CSA Listed Units:

(Optional - CSA Listed Moisture Sensor Cable for 1 phase is 14/2 SOW, 0.530 O.D.)

(Optional - CSA Listed Temperature sensor cable for 3 phase models is 14/2 SOW, .530 O.D.)

(Optional - CSA Listed Moisture & Temperature sensor cable for 3 phase models is 18/5 SOW, 0.476 OD.)

SECTION: D START-UP OPERATION

D-1) Check Voltage and Phase:

Before operating pump, compare the voltage and phase information

stamped on the pump identification plate to the available power.

D-2) Check Pump Rotation:

Before putting pump into service for the first time, the motor rotation

must be checked. Improper motor rotation can result in poor pump

performance and can damage the motor and/or pump. To check the

rotation, suspend the pump freely, momentarily apply power and

observe the "kickback". "Kickback" should always be in a

counter-clockwise direction as viewed from the top of the pump

motor housing.

D-2.1) Incorrect Rotation for Three-Phase Pumps:

In the event that the rotation is incorrect for a three-phase installation,

interchange any two power cable leads at the control box.

DO NOT

change leads in the cable housing in the motor. Recheck the

"kickback" rotation again by momentarily applying power.

D-2.2) Incorrect Rotation for Single-Phase Pumps:

In the unlikely event that the rotation is incorrect for a single phase

pump, contact a Barnes Pumps Service Center.

D-3) Start-Up Report:

Included at the end of this manual are two start-up report sheets,

these sheets are to be completed as applicable. Return one copy to

Barnes Pumps, Inc. and store the second in the control panel or with

the pump manual if no control panel is used. It is important to record

this data at initial start-up since it will be useful to refer to should

servicing the pump be required in the future.

D-3.1) Identification Plate:

Record the numbers from the pump identification plate on both

START-UP REPORTS provided at the end of the manual for future

reference.

D-3.2) Insulation Test:

Before the pump is put into service, an insulation (megger) test

should be performed on the motor. The resistance values (ohms) as

well as the voltage (volts) and current (amps) should be recorded

on the start-up report.

D-3.3) Pump-Down Test:

After the pump has been properly wired and lowered into the basin,

sump or lift station, it is advisable to check the system by filling with

liquid and allowing the pump to operate through its pumping cycle.

The time needed to empty the system, or pump-down time along

with the volume of water, should be recorded on the start-up report.

SECTION E: PREVENTATIVE MAINTENANCE

As the motor is oil filled, no lubrication or other maintenance is

required, and generally Barnes Pumps will give very reliable service

and can be expected to operate for years of normal sewage pumping

without failing. However, as with any mechanical piece of equipment

a preventive maintenance program is recommended and suggested

to include the following checks:

1) Inspect motor chamber for oil level and contamination and

repair as required per section F-1.

2) Inspect impeller and body for excessive build-up or clogging and

repair as required per section F-2.

3) Inspect seal for wear or leakage and repair as required per

section F-3.

4) Inspect motor and bearings and replace as required per

section F-4.

7

Содержание STEP1042L

Страница 16: ...Fig 9 16 ...

Страница 17: ...Fig 10 17 ...