14

Compactor Operation, cont.

Operator and employee responsibilities for compactors

Operators who work on and around

the compactor shall be responsible for the items listed below:

A. Using all applicable safety features provided on the compactor;

B. Using the compactor only after receiving instructions;

C. Reporting any damage to, or malfunction of the compactor by submitting a report to the employer or responsible authority

when the damage or malfunction occurs;

D. Ensuring that access doors and service openings covers are in place, secure, and/or locked before operation begins;

E. Ensuring that the area of operation around container/cart lifting systems and the container will be clear of persons during all

phases of the lifting operation prior to energizing the dumping system;

F. Ensuring that all persons are clear of the compactor point of operation before actuating any compaction cycle controls or con-

tainer/cart lifting system controls and being prepared to stop the compaction cycle or container dumping operation if neces-

sary;

G. Insuring that all persons are clear of the tailgate (on compactor-container combinations so equipped) before the tailgate is

opened or shut. The operator shall warn all persons not to cross behind or under an open tailgate;

H. Using the compactor in accordance with the manufacture’s instructions, including ensuring the proper position of all locks,

doors, guards, etc.;

I.

Ensuring that no one disables or bypasses safety interlocks, switches, or other protective devices and that the compactor is

not operated unless these devices are fully functional;

J.

Locking out the unit when inspecting malfunctions, jams, or other problems arising from daily operations, servicing, or per-

forming maintenance (except maintenance testing). The affected employee shall identify the type and magnitude of the en-

ergy that the compactor uses, shall understand the hazards, and know the methods to control the energy;

K. Coupling and securing a compatible container to a compactor frame as specified by the compactor and container manufactur-

ers);

L. Operating, inspecting, and maintaining the compactor only if 18 years old or older and being properly instructed and trained;

M. Loading, but not operating, the compactor only if 16 years old or older.

Procedure for the control of hazardous energy sources. (lockout/tag-out)

1. The owner/employer shall have a hazardous energy control (lockout/tag-out) procedure to follow when performing servicing

and maintenance on compactors where the unexpected energization or startup of equipment, or release of stored energy

could cause injury to employees.

2. The owner/employer shall utilize the instructions provided by the manufacturer for the control of hazardous energy sources.

The lockout/tag-out procedure shall isolate and render safe all energy sources including electrical, mechanical, hydraulic,

pneumatic, chemical, thermal or other potential energy sources (e.g., gravity, etc). It shall be used to ensure that the compac-

tor is stopped, isolated from all potentially hazardous energy sources and locked out before employees perform any servicing

or maintenance where the unexpected energization or startup of the compactor or release of stored energy could cause in-

jury.

3. The lockout/tag-out procedure shall include but is not limited to the following:

a) Shutting down all power sources;

b) Removing keys or other devices that enable the compactor;

c) Installing a tag on an appropriate location, using a non-reusable fastener, or installing a similar warning device;

d) Placing operating components in such a position so as not to be subject to possible free fall and/or installation of addi-

tional blocking devices to prevent such free fall of any raised or elevated component;

e) Relieving stored hydraulic or pneumatic pressure, after blocking devices are installed, if maintenance is to be done to the

hydraulic or pneumatic system.

4. The procedure shall address the following:

a) Sequence of lockout for the compactor;

1. Notify all affected employees that servicing or maintenance is required on a compactor and that the compactor must

be shut down and locked out to perform the servicing or maintenance.

2. The authorized employee shall refer to the company procedure to identify the type and magnitude of the energy that

the compactor utilizes, shall understand the hazards of the energy, and shall know the methods to control them.

3. If the compactor is operating, it must be shut down by the normal stopping procedure (depress stop button, open

switch, close valve, etc.).

4. De-activate the energy isolating device(s) so that the compactor is isolated from the energy source(s).

5. Lock out the energy isolating device(s) with assigned individual lock(s).

6. Stored or residual energy must be dissipated or restrained by methods such as grounding, repositioning, blocking,

bleeding down, etc.

7. Ensure that the compactor is disconnected from the energy source(s) by first checking that no personnel are ex-

posed, then verify the isolation of the equipment by operating the push button or other normal operating control(s) or

by testing to make certain the equipment will not operate.

Caution

; Return operating control(s) to neutral or “off” position only after verifying the isolation of the equipment.

NOTE: The machine or equipment is now locked out.

Содержание SCR-02

Страница 2: ...2 ...

Страница 4: ...4 ...

Страница 8: ...8 ...

Страница 9: ...9 Operation Section ...

Страница 10: ...10 SAFETY DECALS ...

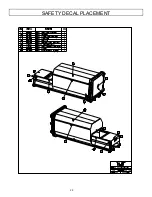

Страница 11: ...11 SAFETY DECAL PLACEMENT ...

Страница 19: ...19 Authorized Technician Maintenance Section ...

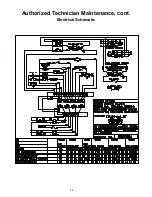

Страница 24: ...24 Authorized Technician Maintenance cont Electrical Schematic ...

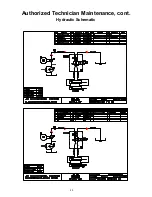

Страница 25: ...25 Authorized Technician Maintenance cont Hydraulic Schematic ...

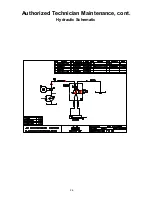

Страница 26: ...26 Authorized Technician Maintenance cont Hydraulic Schematic ...

Страница 28: ...28 Parts Section ...

Страница 29: ...29 SAFETY DECAL PLACEMENT ...

Страница 30: ...30 Installation Section ...

Страница 33: ...33 Hauler Section ...

Страница 35: ...35 Warranty Policy And Procedure Section ...