Compactor Operation, cont.

Owner/employer responsibilities for compactors

The employer/owner shall provide properly

Maintained stationary compactors that meet all applicable regulatory safety requirements and requirements of ANSI Z245.2-2004.

A

Ensuring that the installation of the compactor conforms to local codes, ordinances, and manufacturer’s recommendations.

If installing into a system, examine prevailing safety standards of associated equipment.

B

Providing to employees instruction and training in safe work methods before assigning them to operate , clean, service,

maintain, modify, or repair the compactor. Such instruction and training shall include procedures provided by the manufac-

turer. The employer will maintain records as to the names of employees and the dates of training.

C

Providing instructions for addressing abnormal situations (e.g., bridging of the loading chamber or feeding chute, jam of

materials).

D

Assigning only trained employees to work on (which includes operating, loading, cleaning, servicing, maintaining, or repair-

ing) the compactor.

E

Monitoring the employee’s operation of the compactor and take appropriate action to insure proper use, including adher-

ence to safe practices and the employee requirements of ANSI Z245.2-2004.

F

Repairing, prior to placing the compactor into service, any mechanical malfunctions or breakdowns that effect the safe op-

erations of the compactor.

G

Establishing and following a program of periodic and regular inspections of all compactors to insure that all parts, compo-

nent equipment, and safeguards are in safe operating condition, and adjusted, in accordance with the manufacture’s rec-

ommended procedures. This shall include keeping all malfunction reports and records of inspections and maintenance

work performed.

H

Implementing a program for the maintenance of the compactor which will incorporate the following elements:

1) Requirements for trained, competent maintenance employees or contractors to perform inspection and repair

work;

2) Providing for the cleaning, inspection and repair of the compactor in accordance with the manufacture’s recom-

mendations. Including periodic maintenance;

3) Ensuring that all required safety features are operational and functioning, and repairing, prior to placing into ser-

vice, any reported malfunction or defect that affects the safe operation of the compactor;

4) Ensuring that all caution, warning and danger markings required are installed and legible, or are replaced if dam-

aged, defaced or missing.

I

Utilizing the manufacturer’s recommended procedures for the control of hazardous energy sources (lockout/tag-out) in a

program complying with Part 1910.147 of the Title 29 of the Code of Federal Regulations (OSHA).

J

Utilizing the manufacture’s recommended procedures for access control for permit-required confined spaces as part of the

employer’s program;

K

Protecting any person by one of the methods in 5.9.1, AMERICAN NATIONAL STANDARD Revision of ANSI Z245.2-

2004, or by other means as effective as those means of protection.

L

For compactors fed by means of a loading pit conveyor, reciprocating floor or push pit that is flush with or below the facility

floor, provide;

1. Protection for employees by means of ;

a) Limiting access within 6 feet (183) of the edge of the pit to authorized employees;

b) Training authorized employees to recognize and avoid the hazards associated with the pit area;

c) Requiring that others whose employees use the pit area provide assurance of such training;

d) Limiting access by unauthorized persons by installing signs, such as:

“

RESTRICTED AREA - AUTHORIZED EMPLOYEES ONLY

”

2. Providing a device to the extent practicable, which prevents trucks or other motor vehicles that unload directly into

the loading pit from rolling into the pit.

M When compactor equipped with automatic start/cycling controls are provided, allowing their use only in locations where a

startup alarm is utilized or it is demonstrated that automatic starting does not result in a risk of injury to persons;

N

Providing guard railings for dock ramps that meet U.S. Occupational Safety and Health Administration requirements. These

shall be located around the loading chamber if walk on ramps are used to deposit refuse into the loading chamber. Guard

railings and toe boards shall be provided on the sides of docks and ramps;

O

Providing for an adequate work area around the compactor for safe maintenance, servicing, and cleaning procedures.

P

Keeping all surrounding walking areas and floor free from obstructions, and from accumulations of waste matter, grease, oil

and water;

Q

Specifically inspecting safety interlocks, switches, and other protective devices to ensure that these devices are not dis-

abled or bypassed, and not to permit the compactor to be operated unless these devices are fully functional. These inspec-

tions shall be in accordance with ‘G’;

R

Ensuring that containers supplied are capable of withstanding the maximum forces generated by the compacting system;

S

Ensuring that loaders are aware of hazards and safety requirements;

T

Ensuring that only authorized employees (18 years or older) operate, inspect, or maintain compactors;

U

Ensuring that only authorized employees (16 years or older) load, but do not operate compactors; and

V

Incorporating compactors into the employer’s safety program.

13

Содержание SCR-02

Страница 2: ...2 ...

Страница 4: ...4 ...

Страница 8: ...8 ...

Страница 9: ...9 Operation Section ...

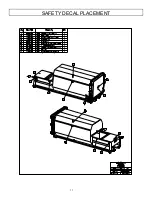

Страница 10: ...10 SAFETY DECALS ...

Страница 11: ...11 SAFETY DECAL PLACEMENT ...

Страница 19: ...19 Authorized Technician Maintenance Section ...

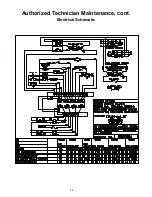

Страница 24: ...24 Authorized Technician Maintenance cont Electrical Schematic ...

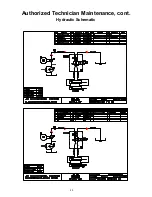

Страница 25: ...25 Authorized Technician Maintenance cont Hydraulic Schematic ...

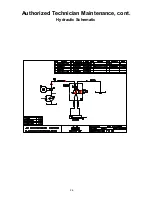

Страница 26: ...26 Authorized Technician Maintenance cont Hydraulic Schematic ...

Страница 28: ...28 Parts Section ...

Страница 29: ...29 SAFETY DECAL PLACEMENT ...

Страница 30: ...30 Installation Section ...

Страница 33: ...33 Hauler Section ...

Страница 35: ...35 Warranty Policy And Procedure Section ...