■

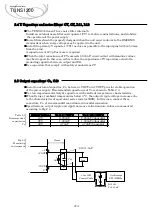

When implementing the power supply to the printed circuit board, please fix the power

supply to the printed circuit board by screw before the soldering.

If it is screwed to the substrate after soldering, there is a possibility of failure by adding

mechanical stress to the soldering point and the internal connections of power supply.

Fig.7.1

Mounting method

■

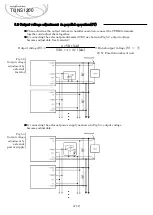

Please measure the temperature on the aluminum base plate edge side when you cannot

measure the temperature of the center part of the aluminum base plate. In this case,

please take 5deg to 10deg temperature margin from the derating characteristics.

■

Use a heat sink that larger than the power supply and has a large thickness so that the

aluminum base plate can be cooled uniformly.

■

The temperature distribution of the aluminum base plate varies depending on the model

and input/output conditions. It is recommended to use the side_B as the reference

because the temperature of the side_B varies little depending on the operating conditions.

Fig.7.2

Effect of heat

sink thickness

(reference)

※

TUNS1200F28 at 100VAC and rated load

7.1 Mounting method

A-17

Applications Manual

TUNS1200

2.1 Pin configuration

7. Mounting method

0

1

2

3

4

5

6

7

8

9

10

0

5

10

15

20

25

⊿

T

(T

c

-

Ts

)

[

℃

]

t : Heatsink thickness

[

mm

]

side_A

side_B

side_C

side_D

Heatsink

Silicone grease

(Momentive YG6260)

External components

TUNS1200F

Printed Board

(FR-4 t=1.6mm)

<Center part of the aluminum base plate.>

(Derating curve temperature)

<Aluminum base plate edge side.>

(In

p

u

t)

(o

u

tp

u

t)

Ts : side_A

Ts : side_C

Ts : side_B

Ts : side_D

Tc : center

t

(mm)

Heat sink

Heat sink

retention screws

Silicone grease

/ Heat dissipation sheet

Power supply

Power supply

retention screws

Power supply

soldering

printed circuit board

①

②