“DEPTH OF DRIVE ADJUSTMENT

The “DEPTH OF DRIVE ADJUSTMENT

flush with the work surface to shallow or deep countersink. First, set the air pressure for consistent

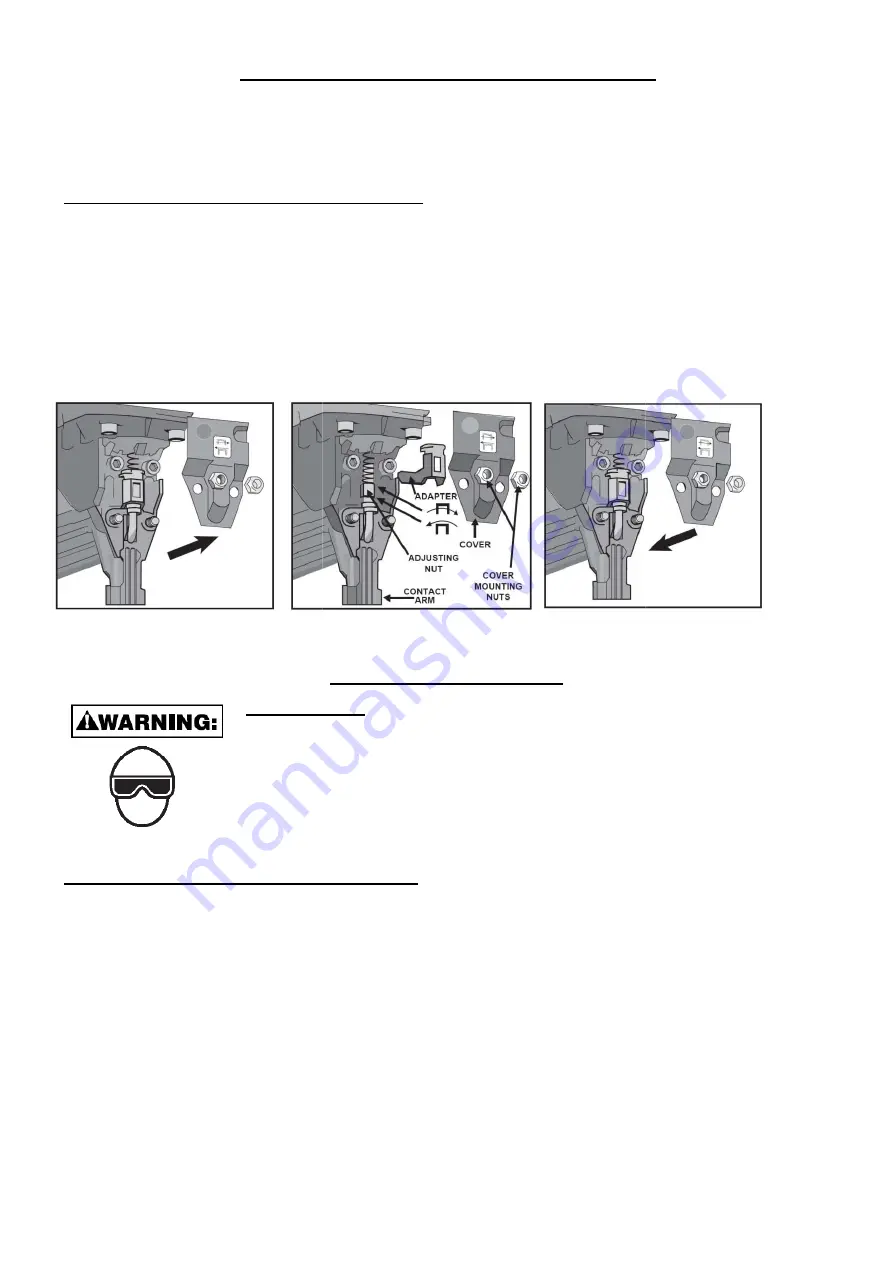

drive in the specific work as described above, then use the

the desired depth of drive.

TO ADJUST “DEPTH OF DRIVE ADJUSTMENT

1. With air pressure set, drive a few fasteners into a representative material sample to determine if

adjustment is necessary.

2. If adjustment is required, disconnect air supply.

3. Refer to label on the outside of door for direction to turn adjusting nut. (See illustration)

4. Remove cover mounting nuts, cover and adapter. Observe the orientation of the flats on the

adjusting nut. Rotate the adjusting nut to the left to increase fastener dri

decrease it. Reorient the flats to be same as before. Reinstall adapter, cover and mounting nuts.

5. Before reconnecting air supply, check that trip mechanism parts operate freely with no binding or

sticking.

6. Reconnect air supply.

EYE PROTECTION

flying particles

the work area

protection is

injury.

The employer

equipment mus

frontal and side

provide adequate

BEFORE HANDLING OR OPERATING

READ AND UNDERS

REFER TO “TOOL

SYSTEM ON YOUR

There are four available systems on the

1. CONTACT TRIP OPERATION

4. REMOTE FIRE

DEPTH OF DRIVE ADJUSTMENT”

DEPTH OF DRIVE ADJUSTMENT” feature provides close control of the fastener drive d

flush with the work surface to shallow or deep countersink. First, set the air pressure for consistent

work as described above, then use the “DEPTH OF DRIVE ADJUSTMENT

DEPTH OF DRIVE ADJUSTMENT”:

With air pressure set, drive a few fasteners into a representative material sample to determine if

If adjustment is required, disconnect air supply.

to label on the outside of door for direction to turn adjusting nut. (See illustration)

Remove cover mounting nuts, cover and adapter. Observe the orientation of the flats on the

adjusting nut. Rotate the adjusting nut to the left to increase fastener drive depth, or to the r

the flats to be same as before. Reinstall adapter, cover and mounting nuts.

Before reconnecting air supply, check that trip mechanism parts operate freely with no binding or

TOOL OPERATION

PROTECTION which conforms to ANSI/ CE specifications and

particles both from the FRONT and SIDE should ALWAYS be worn

area when connecting to air supply, loading, operating

required to guard against flying fasteners and debris,

employer and/or user must ensure that proper eye protection

must conform to the requirements of the ANSI Z87.1 and 89/86/EEC,

side protection. NOTE: Non-side shielded spectacles

adequate protection.

TING THIS TOOL:

UNDERSTAND THE WARNINGS CONTAINED IN THIS

OOL SPECIFICATIONS” IN THIS MANUAL TO IDENTIFY

YOUR TOOL.

the pneumatic tool:

TION 2. SEQUENTIAL TRIP OPERATION 3. TRIGGER OPERATED

8

”

feature provides close control of the fastener drive depth; from

flush with the work surface to shallow or deep countersink. First, set the air pressure for consistent

DEPTH OF DRIVE ADJUSTMENT” to give

With air pressure set, drive a few fasteners into a representative material sample to determine if

to label on the outside of door for direction to turn adjusting nut. (See illustration)

Remove cover mounting nuts, cover and adapter. Observe the orientation of the flats on the

ve depth, or to the right to

the flats to be same as before. Reinstall adapter, cover and mounting nuts.

Before reconnecting air supply, check that trip mechanism parts operate freely with no binding or

and provides protection against

worn by the operator and others in

operating or servicing this tool. Eye

debris, which could cause severe eye

protection is worn. Eye protection

and 89/86/EEC, and provide both

spectacles and face shields alone do not

THIS MANUAL.

IDENTIFY THE OPERATING

3. TRIGGER OPERATED